EN 1090-3

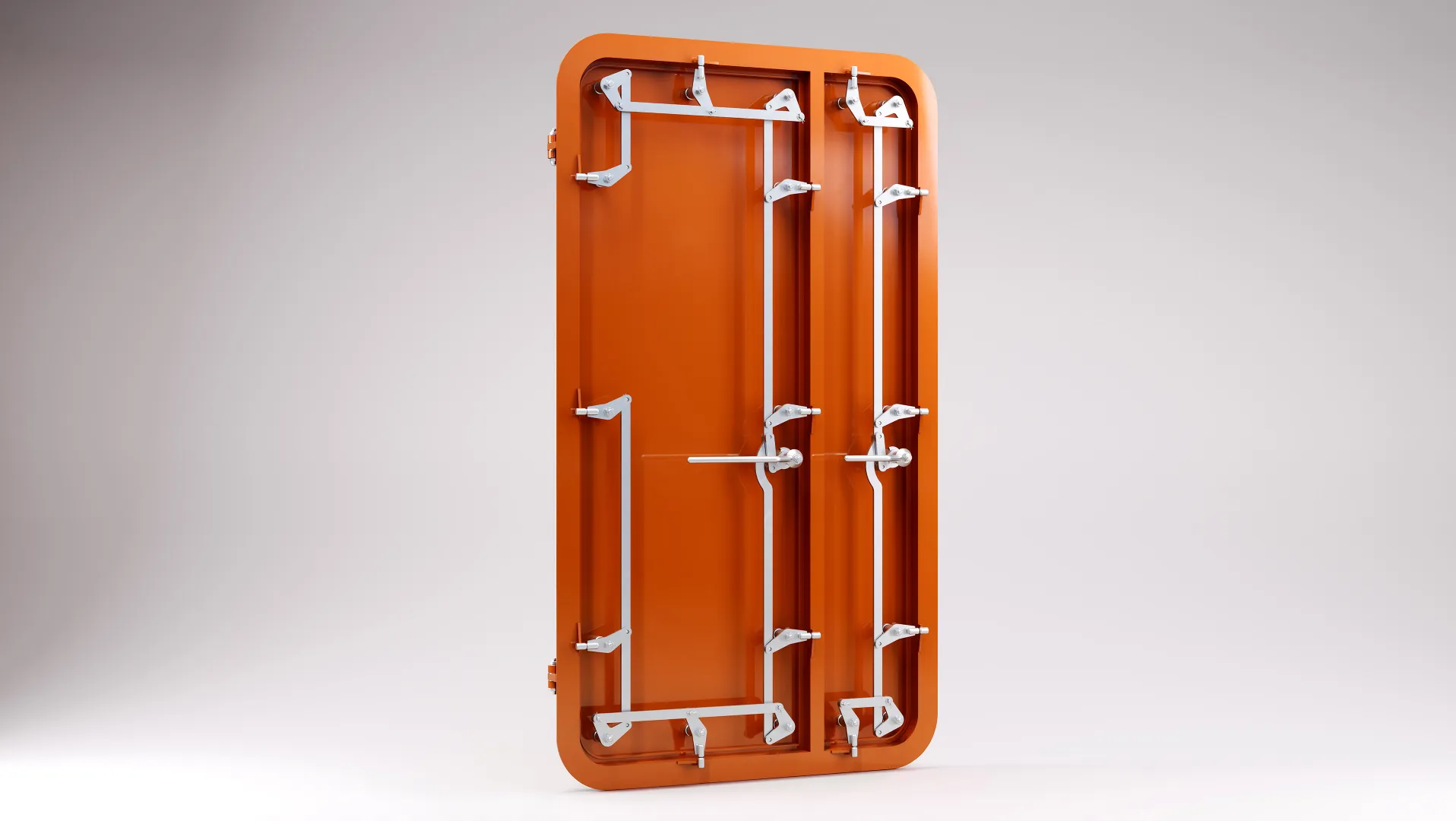

KAMI can deliver aluminum steel structures up to EXC3 – execution class 3

At KAMI, we are certified to weld and CE mark aluminum structures according to EN 1090-3, up to Execution Class 3 – also referred to as EXC3 / EX3. If you need a staircase or balcony welded or other aluminum structures welded according to EN 1090-3, contact us. We ensure that your product is CE marked to comply with applicable regulations.

Aluminum structural steel must be CE marked according to EN 1090-3

KAMI is certified to produce and CE mark according to EN 1090 in the materials black and stainless steel and aluminum. The EN 1090 standards are based on the manufacture of structural steel, but at KAMI we see more and more constructions being specified according to the EN 1090 standards.

Certified EN 1090 FPC system – built according to the ISO EN 3834-2 standard

At KAMI, we have a certified and audited EN 1090 FPC (Factory Production Control) system. This means that we have to carry out CE marking of the steel we manufacture. The FPC system is built on EN ISO 3834-2 standard (quality requirements for fusion welding), and the overall welding quality assurance system is finally implemented into our ISO 9001:2015 Quality Management System – the overall quality assurance system.

Internal welding coordination offered

We have our own in-house welding coordinator, so we can discuss welding and potential optimizations with you if needed. At KAMI, we always strive to ensure the most cost-effective production – also when it comes to welding. Cost out and continuous improvement is something we work on all the time, so if we can see potential improvements in terms of efficiency, faster lead times and higher quality, we’ll present this to you and together we can discuss the best solution.

Aluminum surface treatment

We can surface treat aluminum with anodizing / anodizing or we can perform in-house ceramic blasting. We can also provide wet or powder coating according to DS/EN ISO12944-C5M. Corrosion classes C1-C5 can be carried out depending on the choice of surface treatment system, and all systems can be documented with relevant reports, such as a measurement report.

Installation – internal or external

KAMI can help you with assembly – internally or externally – if desired. If your structural steel needs to be installed / erected correctly according to EN 1090, we know the standard to ensure that the project is delivered according to the standard. Among other things, we work with customized control and check sheets – even when installation is included in the delivery.

Preparation of final documentation

When we deliver products according to EN 1090, we ensure that you as a customer receive the complete final documentation, which is the Declaration of Performance and the CE marking itself. At KAMI, we can document 100% traceability of internal and external processes and, based on this, we can issue final documentation according to EN 1090-1. The CE marking itself is your guarantee that all documentation for the production of the product has been carried out according to the standard. In addition to production and CE marking in aluminum, we are also certified to deliver building steel in black steel and stainless steel, read more via the link EN 1090-1.

We can prepare calculation and production documentation

KAMI manufactures – but in addition, through our own engineers – we can also calculate and prepare production documentation of steel structures according to EN 1090-2. Our engineering department is audited and certified according to EN 1090-2, so all calculations and drawings can be prepared according to applicable standards, including EUROCODES.

If you want to read more about our competencies in structural steel engineering, you can find info here. If you want to read more about our general competencies within mechanical design and calculations, you can find more info here here.

Sub-processes, construction or delivery of a complete project – you decide!

One of KAMI’s strengths is that we provide sheet metal processing, machining, welding – and construction. This allows us to manage the entire value chain from idea to delivery of the finished solution. We deliver everything from relatively complex steel structures to simple sub-components. At KAMI, we can take care of the entire design process or you can provide finished drawings – it’s entirely up to you. Our long history, dedicated long-serving employees and know-how in sheet metal working, machining and construction give us the skills to solve most tasks in mild steel, stainless steel and aluminum. We deliver exactly what you need – nothing is too small and nothing is too big!

Please contact us about EN 1090 and read more about us below

KAMI can be your complete supplier, as we can design and document your project from the initial idea to production and CE marking. We can also deliver a part of your job – for example, a one-off process such as cutting or bending – we take care of the part(s) of a project you want done! Examples of different sub-processes we provide for metal processing are cutting, welding, bending and rolling and CNC machining.

In addition to producing according to EN 1090, we also carry out complete projects. Much more info on selected projects can be found via this link. Whether you need metal design, calculation or production, you are more than welcome to contact us for a no-obligation chat about the possibilities!

Contact us to find out what we can do for you

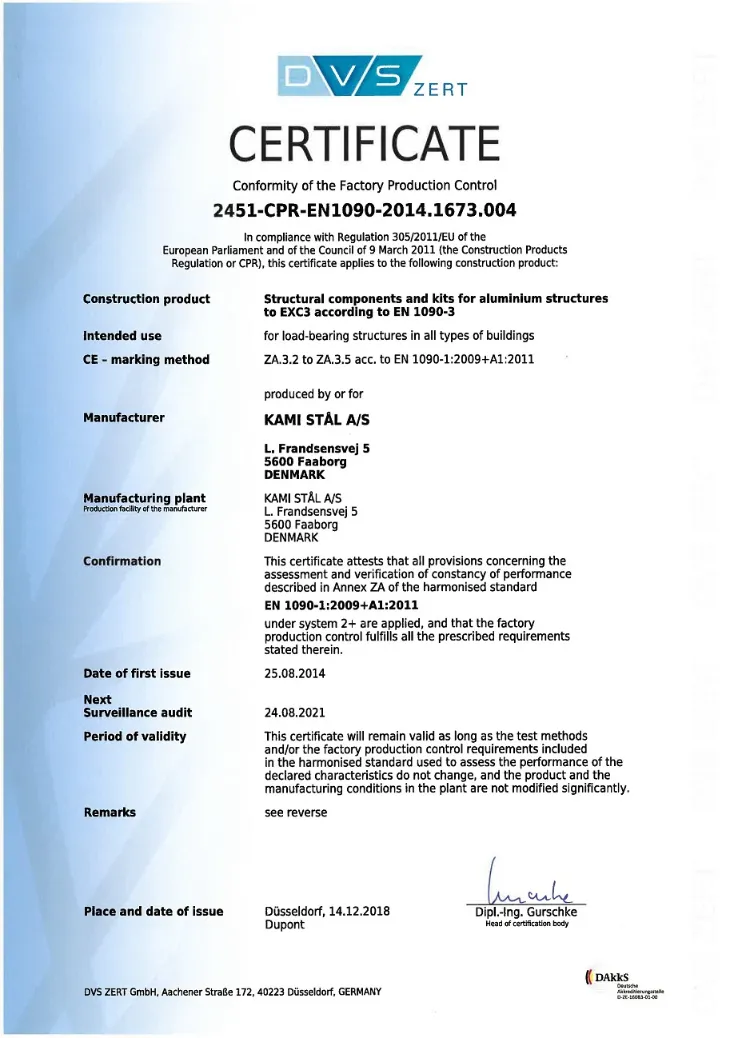

Certifications and diplomas

See all of KAMI's certifications and diplomas below, click on the individual links to read more.

FPC (Factory Production Control) CE marking of mild steel and stainless steel structural steel

Document

The Danish Veterinary and Food Administration

Link

We work within Industry, Offshore & Marine, and Structural Steel

We deliver everything from small welded structures to large structures!

We also deliver small CNC machined parts – and nothing is too small!

Industry

Offshore & Marine

Structural steel