Twin Screw for surimi

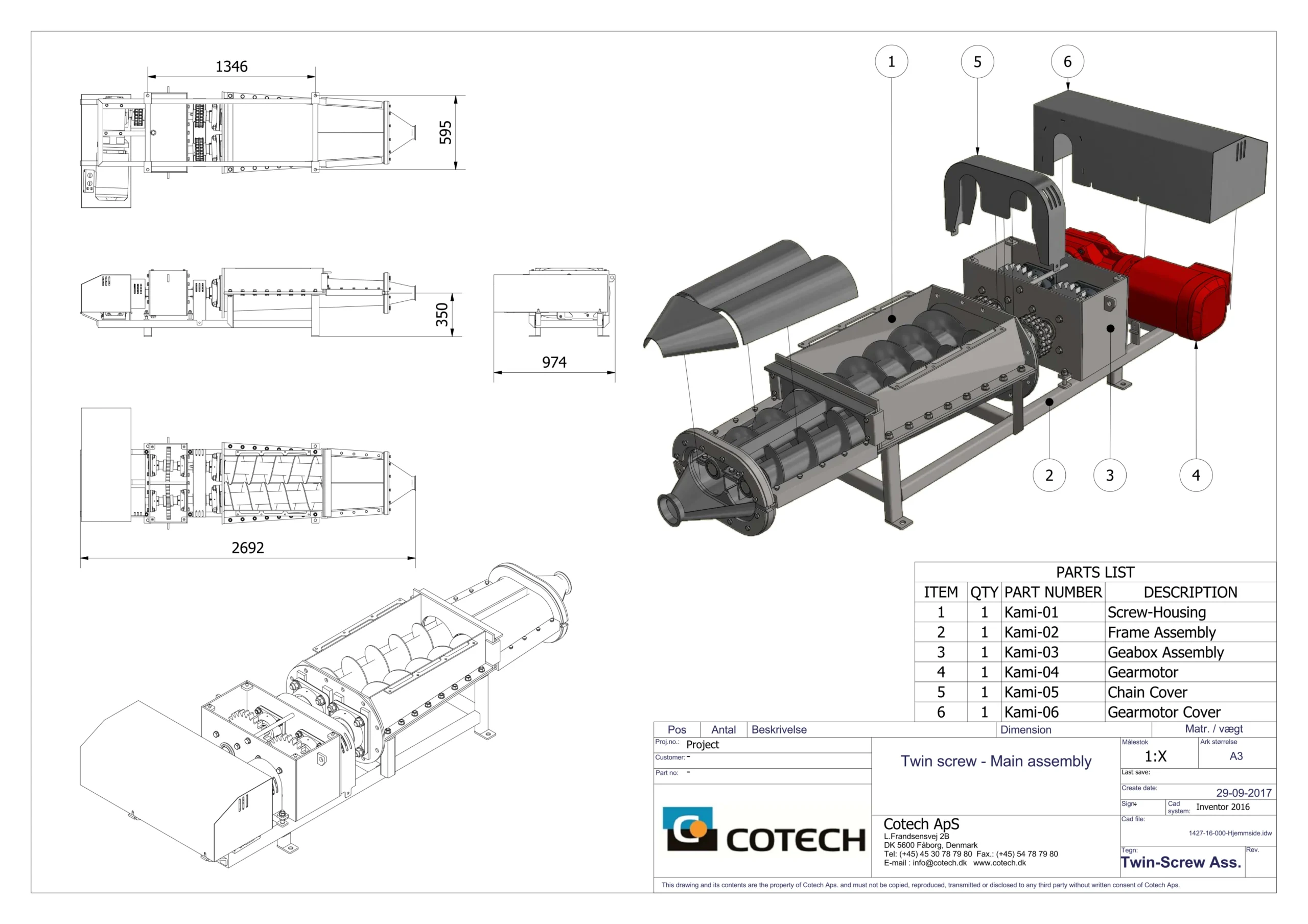

KAMI has designed and manufactured the Twin Screw for surimi production

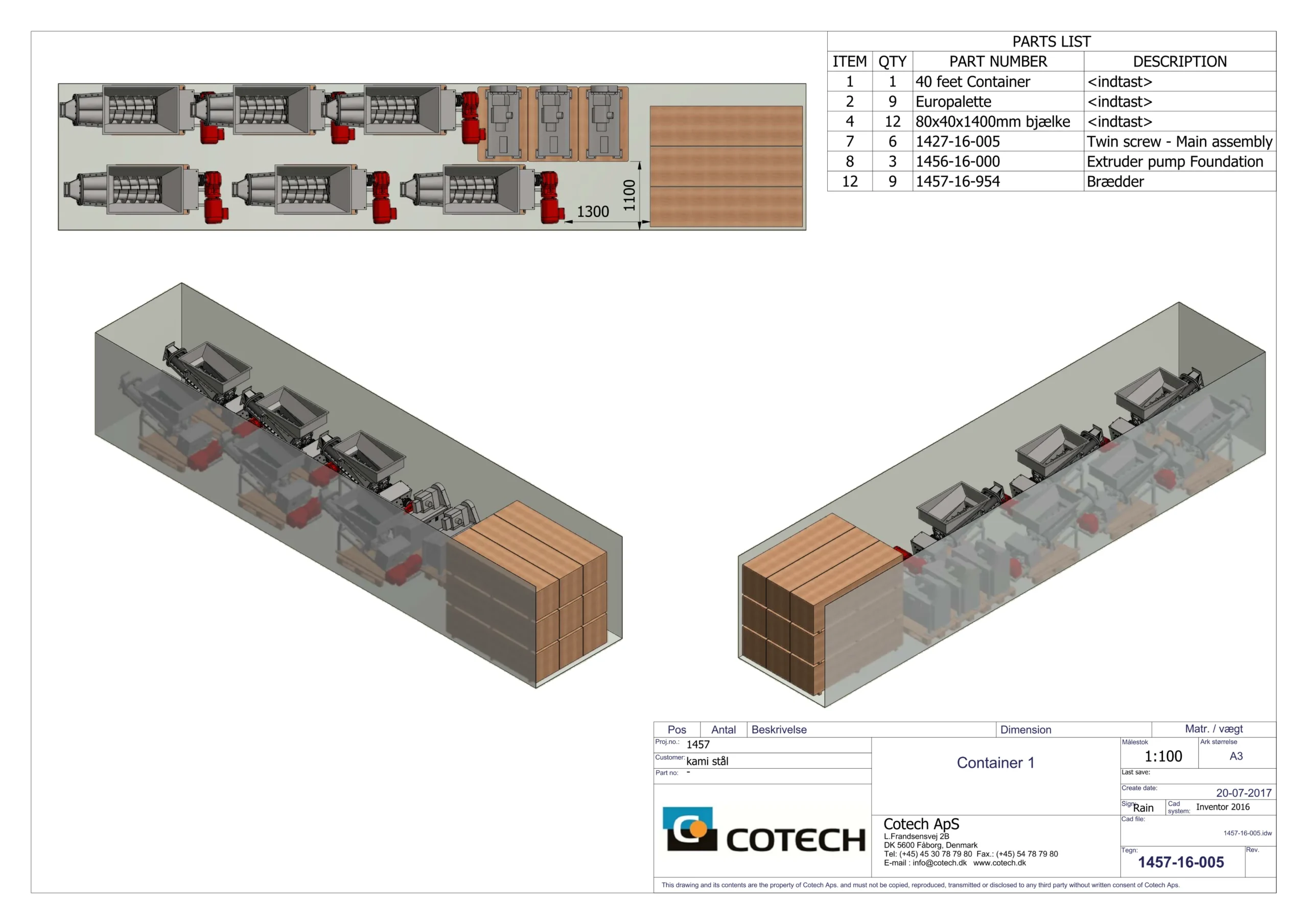

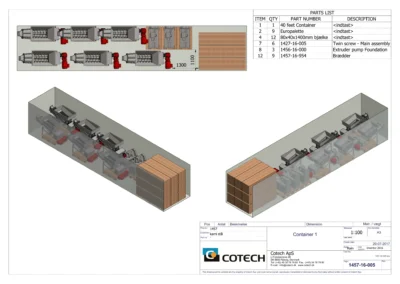

In collaboration, KAMI’s engineering and production department has completed this project, which is a Twin Screw for surimi production. The machine is part of a larger delivery to our US branch in Seattle. In order to deliver the machine, we have carried out engineering, production and documentation. After final assembly, the machine is FAT-tested in production to ensure everything works before shipping to Seattle.

The machine is part of a larger layout/factory facility on a ship that fishes surimi, which is the main ingredient in the California roll sushi (see more at en.wikipedia.org). The ship is fishing off the coast of Alaska, and if you want to know more about surimi, you can find info via this link: zoeescher.com.

If you want to know more about our production facilities in the US, you can find info here, and you are also very welcome to visit our US website, which tells much more about our activities in Seattle www.kamitech.com.

Video of surimi mixer and extruder

Construction

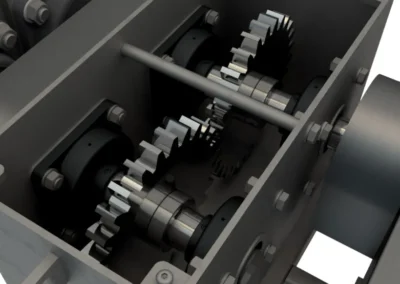

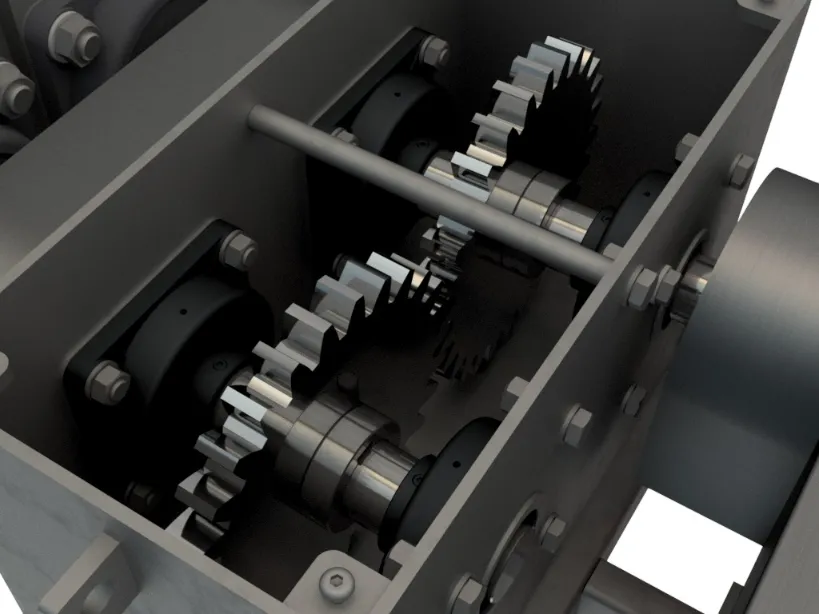

- Complete machine design

- Preparation of the production basis

- Identification of spare parts for the machine

- Preparation of final documentation, including manual.

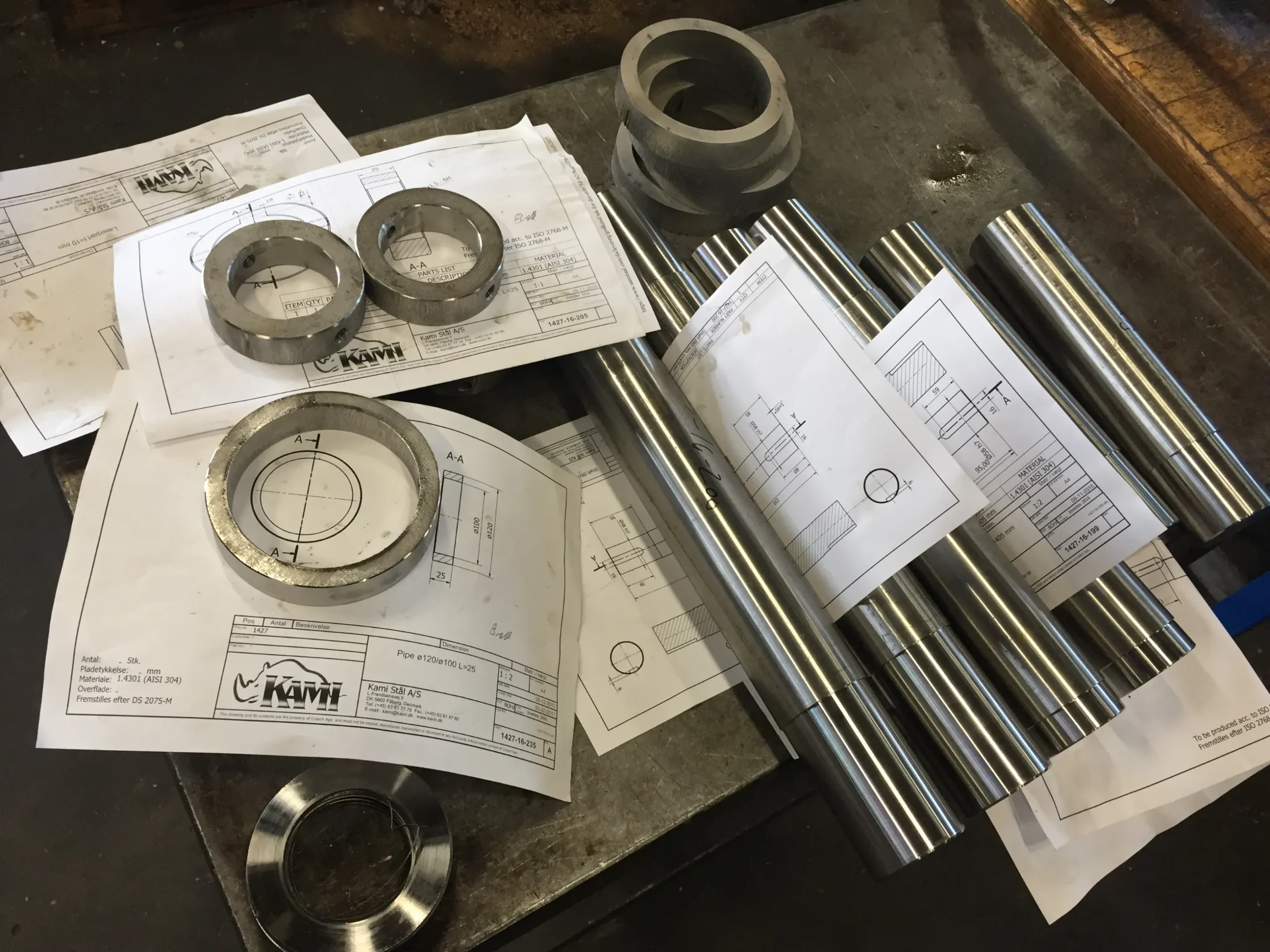

Production

- KAMI’s stainless steel department produced the machine.

- Manufacturing processes include cutting/bending, CNC machining, welding, ceramic blasting and assembly.

- The finished machine is FAT tested before shipment.

Delivery

- The project is delivered to Kami Tech Inc. which is our US office in Seattle.

- Kami Tech Inc. has installed the machine at the end customer.

- The machine is delivered with customer-specific documentation.

- A great project from A-Z with engineering and production.

We work within Industry, Offshore & Marine, and Structural Steel

We deliver everything from small welded structures to large structures!

We also deliver small CNC machined parts – and nothing is too small!

Engineering and project delivery

We offer design, FEM calculation and CE marking

Stainless steel and aluminum production

We offer sub-processes or complete designs

Production in mild steel and high-strength steel

We deliver everything in sheet metal, welding and machine work

Want to learn more about this project?

Then please contact us!

We deliver projects for general industry and the food industry. KAMI carries out many different projects in stainless steel and aluminum, as well as in black steel and high-strength steel.

If you would like us to help you with your next project, please contact us. For more information on some of the projects we have delivered to industry, see here. In addition to projects for industry, KAMI delivers projects for the offshore & marine industry – more info on relevant projects can be found here.

KAMI can deliver your complete project, but we also provide sub-processes for the metal industry, such as cutting, shearing, bending and rolling, CNC machining and welding. You can see more about everything we deliver here. We also provide separate engineering services, such as design, production basis preparation, FEM calculations and CE marking. Much more info on what we offer in terms of engineering can be found here.

Feel free to contact us, whether you’re looking for manufacturing or engineering, or the combination – KAMI is ready to help you!