Brainstorming / development work

KAMI can mature ideas and be your development partner

We can act as an effective sparring partner and be your development partner, from the moment you come up with the idea, through design and production, to manufacturing and ready for testing and delivery to your customer.

Development and sparring

You can connect KAMI to your development process, regardless of where you are in the process. We can jump in wherever you want, and whether you’ve just had the idea or you’re further along in the process, it doesn’t matter – we’ll help you where it makes sense!

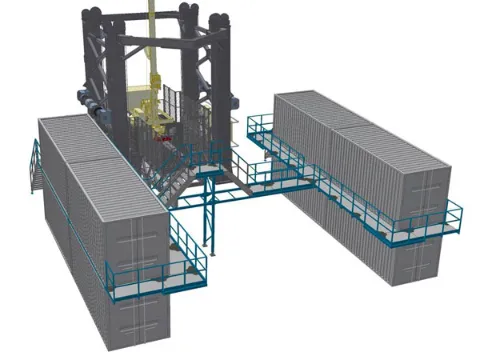

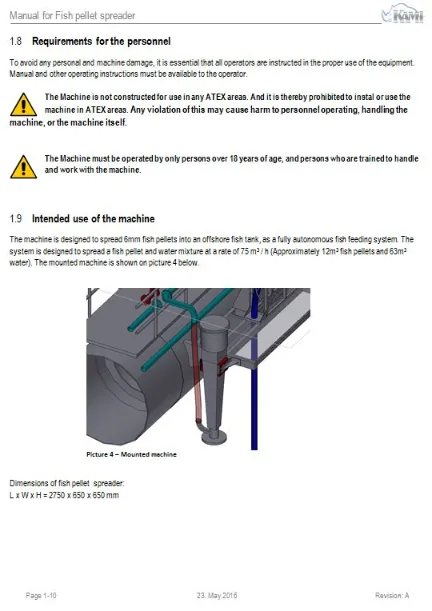

We have participated in many projects in many industries, so we have the skills to give you feedback on your idea or project. KAMI has carried out many engineering assignments for industry, for example in the food and recycling industry, and in addition to general industry, we also carry out assignments for the offshore & marine industry. All in all, we have a wide range of know-how to ensure you get the right advice.

Production optimization

KAMI can be involved from the start and ensure that the end product is production optimized. We have access to production facilities, so we are always aware of whether a product or idea can be optimized for the easiest possible manufacturing. We are familiar with most metal fabrication technologies and can advise you on what it takes to get the best – and cheapest – end result! Cost out is a focus area for us at all times – we ensure focus on a solution that is optimized for production for high quality, low lead time and low production costs.

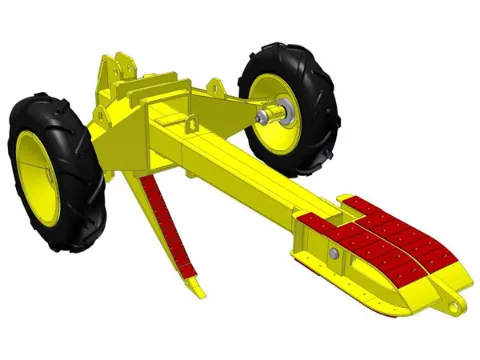

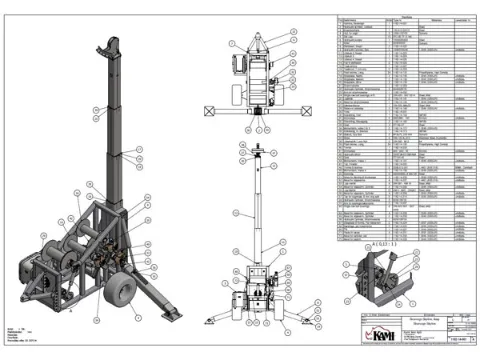

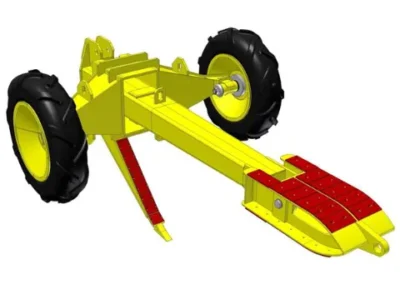

Have your concept design constructed and, if desired, optimized via FEM calculations

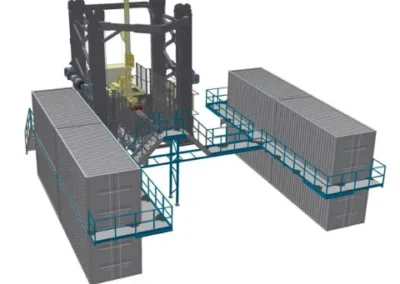

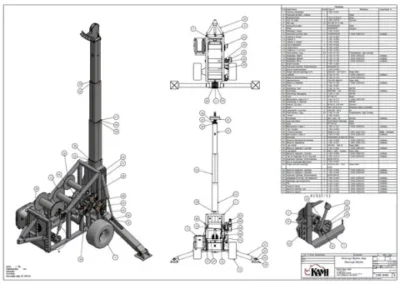

In addition to sparring / sketching and production optimization, we can determine the final design. Using our 3D CAD programs, we can model the ideas we have come up with. This visualizes whether everything is as it should be and provides input for any further course of action.

If it makes sense, we can calculate the design to identify any material savings. Through FEM calculations, hot spots can be localized and the correct strength dimensions can be determined. For heavier structures – or if there is a requirement for any calculations to prove that the structure will hold up – we can perform relevant calculations using our CAD program or by hand calculations. If you want to know more about what we offer in construction and FEM calculations, you can find more info here here.

Production and final documentation

After a design phase, we can help bring your idea to production. We can prepare production documentation with full drawing bases and cutting files, and have access to production in stainless and aluminum, as well as black and high-strength steel. If you need production, we can also help you with that part – if you wish. We can easily perform engineering tasks without the need for a production phase, you choose what suits your concept. If you need some form of final documentation, we can help you with that. The level of involvement is entirely up to you – but we can be involved from A-Z – if you want us to be!

CE marking

For example, if you need a machine delivered, we can help you get it CE marked. We can take care of everything related to CE marking, including risk assessment and preparation of the technical file. If you want to read more about what we offer within CE marking, you can find more info here here.

Feel free to contact us for a no-obligation chat about how we can help you. Through our engineering department and our access to production facilities, we can be involved from start to finish – we are there where it makes sense and where we can add value to your idea/project!

We also offer services like these

Design and calculation

Visualization