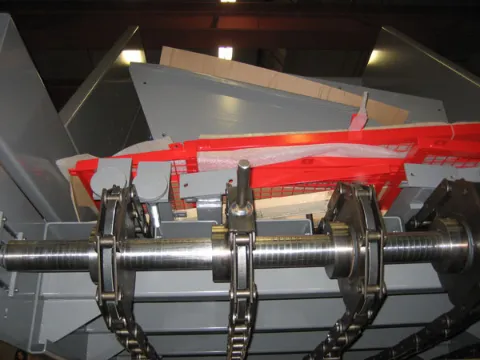

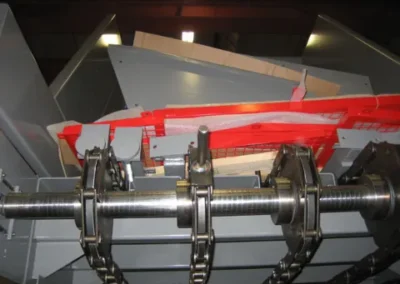

Surface treatment

KAMI offers surface treatment, in-house or through external partners

KAMI supplies many structures and items with surface treatment. We offer several different coating methods. Most often, the steel is treated with wet or powder coating via an external partner.

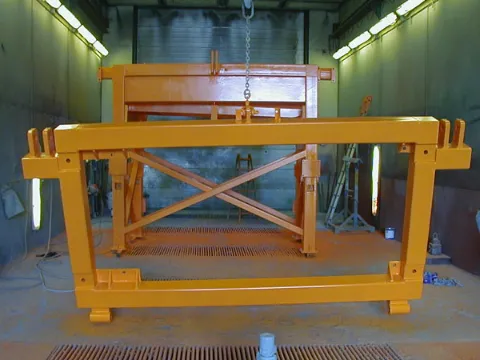

Surface treatment with wet or powder coating, or with E-Coat

In addition to wet and powder coatings, we also offer E-Coat surface treatment through a selected partner. E-Coat is a dipping process that is good for complex items. With this type of surface treatment, you can achieve a very good corrosion class. However, if a specific RAL color is required, we have to give the E-Coat a final coat.

Metallization

In addition to the above processes, we also offer metallization. Metallization, like E-Coat, is good against corrosion and this method is most often used as a pre-treatment. However, like galvanizing, the treatment can stand alone without any kind of finishing/finish coat.

DS/EN ISO12944-C5M as well as MOTS and Norsok standards

Our offshore deliveries are coated to many different systems, such as DS/EN ISO12944-C5M as well as MOTS and Norsok standards. We’ll coat to the standard you specify, and we can comply with any documentation requirements.

Full documentation (measurement report)

All our deliveries can be delivered with full documentation (measurement report), and in addition, a FROSIO report can also be prepared via an external inspection body if you require this.

Galvanization – also according to EN 1090 standard

Steel structures and items can be supplied with galvanization via an external partner, and if required, we can provide full documentation. For example, we can have the surface treated / galvanized to EN 1461 if you wish. The delivery is thus approved to comply with EN 1090.

Anodizing / anodizing of aluminum parts and pickling

Aluminium parts and structures can be supplied anodized. Stainless steel items and structures can be delivered pickled, either as spray or dip pickling. Both processes are managed externally, but KAMI is responsible for the quality, which we control through our DS/EN ISO 9001:2015 Quality Management System.

Ceramic blasting

Internally, we perform ceramic blasting of both stainless steel and aluminum. If you want to know much more about this process, you can find info about it here here.

Contact KAMI for a quote on surface treatment

KAMI supplies many steel structures and can service you from A-Z. In addition to manufactured in black steel, high-strength steel, stainless and aluminum we also provide engineering services.

Finally, we provide many different types of surface treatment, so you are more than welcome to contact us if you want to know more about the possibilities – we are ready to serve you!

Contact us to find out what we can do for you

We also offer services like these

High strength steel

Prototyping