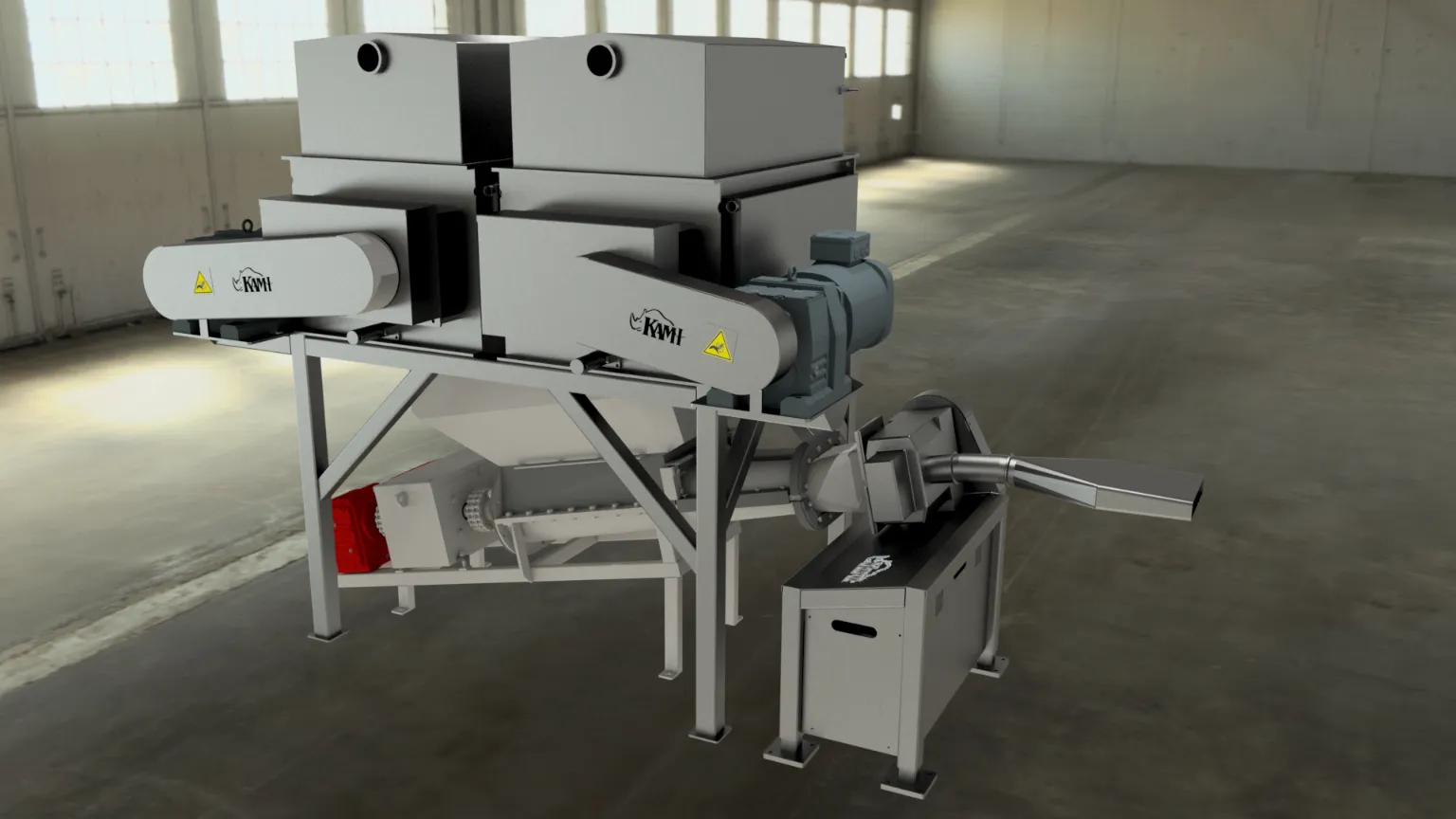

Mixer for surimi

KAMI has developed and delivered a machine for surimi production

KAMI’s engineering and production departments worked together to deliver this project. The project was delivered to our Seattle, USA office. The overall project has included engineering, production and documentation. Before shipment, the equipment is FAT-tested in our production to ensure functionality.

The equipment is used on factory ships that, among other things, fish in the cold waters off Alaska. The machine/mixer is used to transport the surimi further in the process. If you want to know more about surimi, you can read more about surimi at en,wikipedia.org.

If you want information about our production facilities in the US, you can find more info at here, and if you want to know more about our activities in Seattle in general, here is a direct link to our US website: www.kamitech.com.

TIG welding in stainless steel, aluminum and mild steel

We TIG weld primarily stainless steel and aluminum. In stainless TIG welding, we weld in AISI 304 and AISI 316, but we also weld in more corrosion-resistant stainless materials, such as Duplex.

In addition to Stainless steel welding and aluminum we also perform TIG welding in black steel. We use TIG welding for thinner materials, but we also weld machine frames and other structures, so the process is widely used in both of our departments, including black steel, stainless steel and aluminum.

Pipe welding in stainless steel and mild steel

In addition to welding various structures, we also perform pipe welding in stainless steel, aluminum and black steel. We can provide regular pipe welding, but in addition to this, we can also offer pipe welding via rotary table welding. Using the rotary table, the pipes rotate automatically during the welding process, allowing us to perform a partially automated process.

Pipe welding produced via a rotary table provides a consistent result and will often also increase efficiency, reducing the cost of the weld.

Video of surimi mixer and extruder

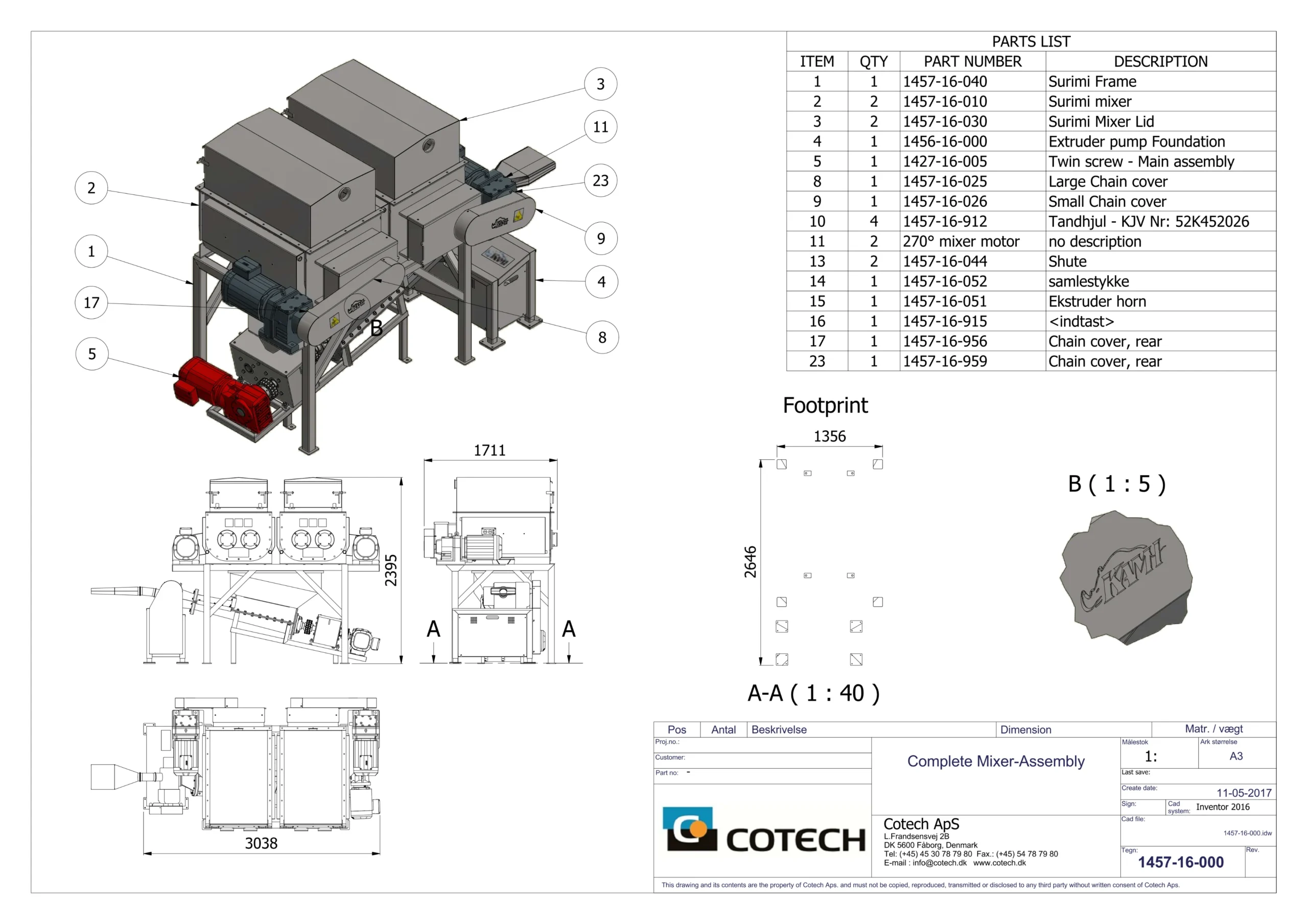

Construction

- Specifying engines, clarifying interfaces etc.

- Creation of the complete manufacturing base for the production of the equipment

- Identification of relevant spare parts

- Preparation of final documentation, including manual.

Production

- KAMI’s stainless steel production section has produced the equipment – everything is made of stainless steel.

- Processes include cutting/bending, CNC machining, welding, ceramic blowing and assembly.

- After final assembly, the complete machine is FAT tested.

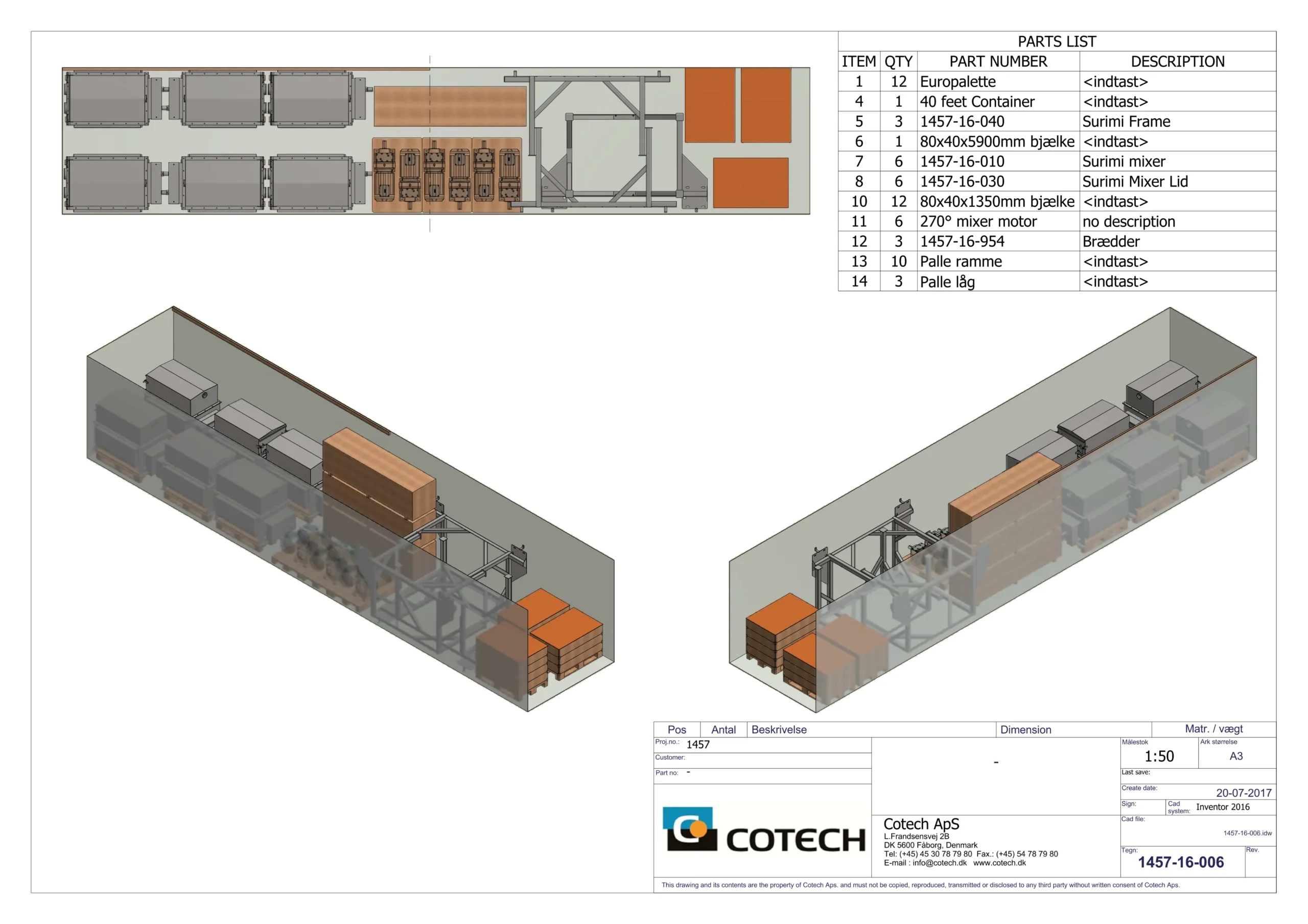

Delivery

- The project was delivered to our US branch, which carried out the installation at the end customer.

- Equipment is delivered with customer-specific documentation.

- An exciting stainless steel project – where our departments worked together to come up with a great product.

We work within Industry, Offshore & Marine, and Structural Steel

We deliver everything from small welded structures to large structures!

We also deliver small CNC machined parts – and nothing is too small!

Engineering and project delivery

We offer design, FEM calculation and CE marking

Stainless steel and aluminum production

We offer sub-processes or complete designs

Production in mild steel and high-strength steel

We deliver everything in sheet metal, welding and machine work

Want to learn more about this project?

Feel free to get in touch with us!

KAMI delivers projects to industry, including the food industry. We carry out a wide variety of projects in stainless steel, aluminum, black steel and high-strength steel.

Feel free to contact us if you need advice on your next project. For more information on some of the projects we have delivered to industry, see some of our selected projects here. In addition to industrial projects, we also deliver projects for the offshore & marine industry. More info on some of these projects can be found here.

In addition to delivering complete projects, we also provide a lot of sub-processes for the metal industry, such as cutting, bending/rolling, CNC machining, welding and assembly. For more info on our different processes, please see here. In addition to production, KAMI is also able to provide separate engineering services, including design, production basis preparation, FEM calculations and CE marking. If you want to know more about what we offer in engineering, read more about our services here.

You are more than welcome to contact us, whether you want manufacturing or engineering, or both – we will do our best to serve you!