Sourcing

Sourcing steel production

We can ensure you get the right price for your steel blanks / steel structures through our long-standing sourcing partner. If you’re already getting items from low-wage areas, we can match the price, and we can ensure the correct quality through on-site self-monitoring if deemed necessary.

We have worked with our partner for many years, so we are fully aware of what is possible when it comes to delivery times, tolerances, quality and other relevant parameters.

If we assess that there are critical processes in the delivery, such as high demands on surface treatment, we can have the steel produced by our sourcing partner and handle test assembly and surface treatment in Denmark.

After reviewing the drawings and based on the desired delivery time, we can assess whether low-cost production is an option – your guarantee of competitive prices!

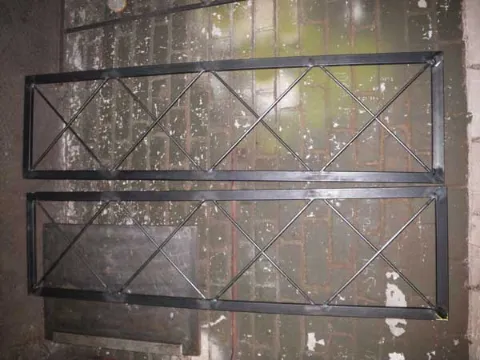

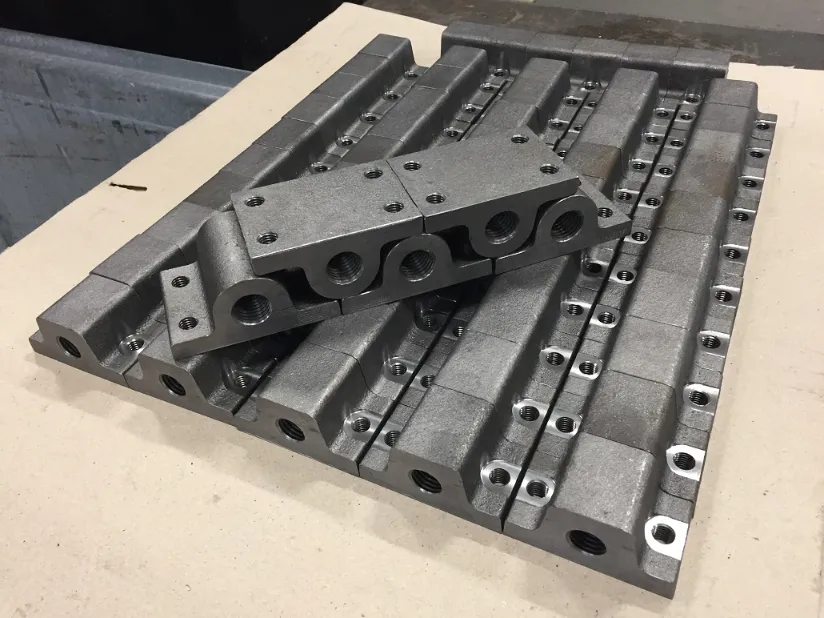

Large and small productions – in mild steel, stainless steel and aluminum

Whether you need to source sub-parts for your production or supply larger complete steel productions, we can help you. We deliver everything from small CNC machined parts to large welded constructions, such as platforms and machine stands. We supply items in mild steel, stainless steel and aluminum. To see the variety of what is delivered, you can view a wide selection of items from our partners in the gallery.

Possible prototyping at KAMI – focus on cost out

For new development of new critical parts/structures, you can use our set-up for

Prototyping

in Denmark. This means that everything can be clarified locally with us, so we can work together to ensure the right quality – even the quality that is often difficult to document in the drawings. KAMI can then work with our partner to produce at the cheapest price.

In addition to quality, we focus on cost out and derived price reduction – we review drawings and specifications – and suggest improvements if there is something that can be done faster and cheaper. We want to make sure you have a competitive product that can be produced – and therefore delivered – with the shortest possible lead time.

Updating documentation if necessary – and subsequent sourcing

Through our in-house engineering department, we can ensure that documentation is prepared for sourcing, minimizing potential errors. We can review drawings and ensure the right tolerances – maximizing time and quality during production. Tolerance setting of working drawings is very important to us – regardless of whether it is to be produced in Denmark or in other countries.

Our sourcing partner, like KAMI, has experience with stainless steel production and constructions in

aluminum

and

black steel

. We offer most metal processes as low cost – everything from sheet metal processing, including laser and plasma cutting, cutting, bending and rolling tasks, for welding workpieces, CNC machining and surface treatment. Surface treatment can be offered as galvanizing, wet painting or powder coating.

KAMI can manage the sourcing process – from start to finish

We can start your sourcing from scratch or make alternative offers to what you’re already getting delivered.

In addition to supplying from our own partner, we can also, if you wish, manage your current suppliers, freeing up time for your core competencies.

Sourcing through KAMI ensures a single-point of contact. We speak Danish and can easily understand your issues. In short, we can do it all – we call it “intelligent and seamless sourcing”!

All in all, KAMI can be your total supplier when it comes to low-cost production – with all the benefits it gives you as a customer. Please contact us for a no-obligation chat, and together we can see if we can help you with your sourcing task.

In addition to sourcing, KAMI can be your warehouse hotel

KAMI can stock your products/productions based on a given special agreement/framework agreement – we call it “Vendor Managed Inventory “.

Several of our customers already use the concept where we produce to stock, ensuring just-in-time delivery!

Read much more about the possibilities to reduce your costs through inventory management here.

Vendor-managed warehouse