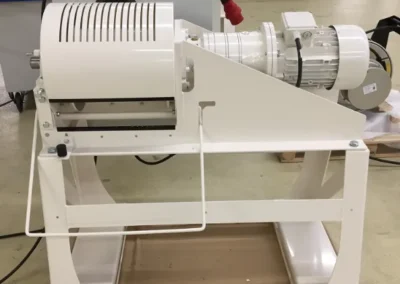

Aircraft retract winch

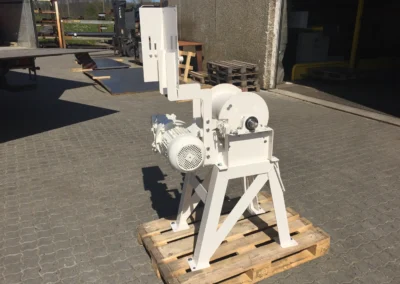

KAMI has delivered winches for aircraft retraction

In collaboration, our engineering department and production department managed this project. Our supplier of electrical and hydraulic controls wanted us to participate in the project as we could handle the mechanical design, prepare production documentation, and produce and get approval for a prototype including CE marking.

The electrical and hydraulics part is specified by our partner.

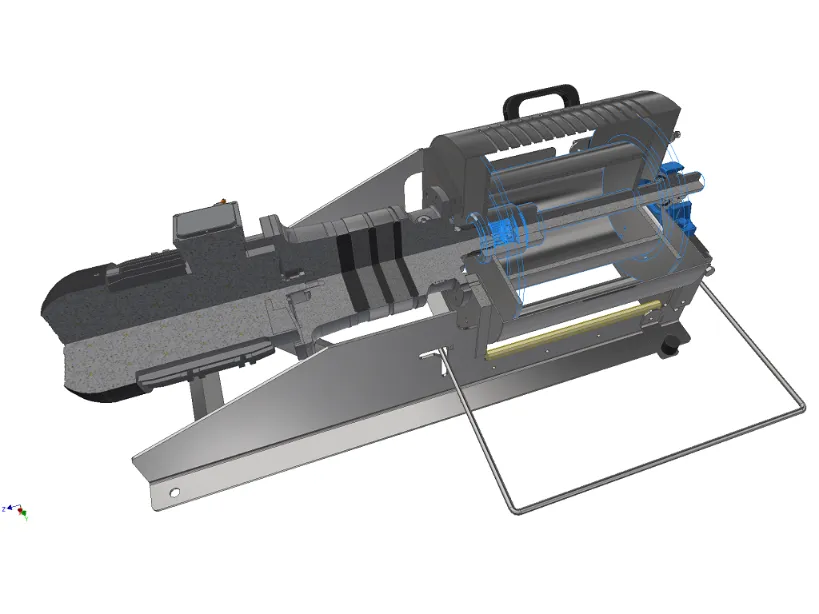

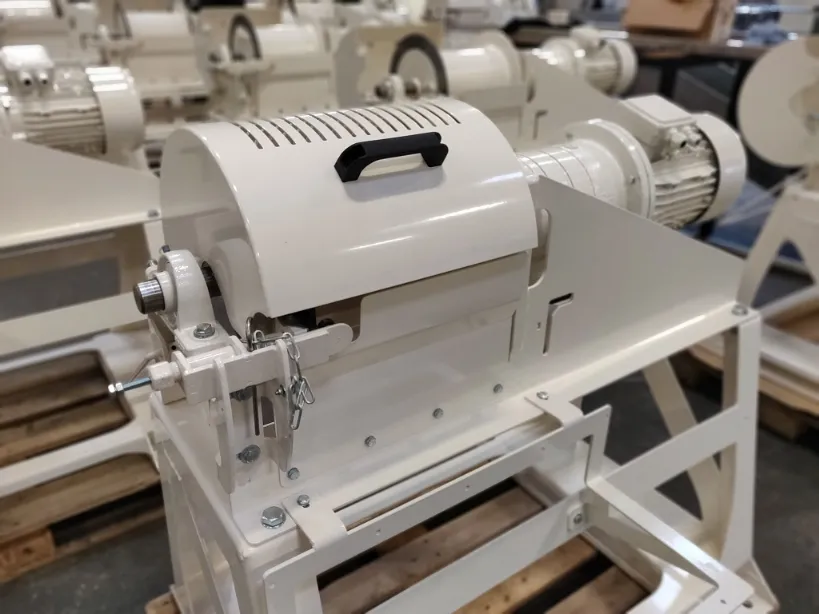

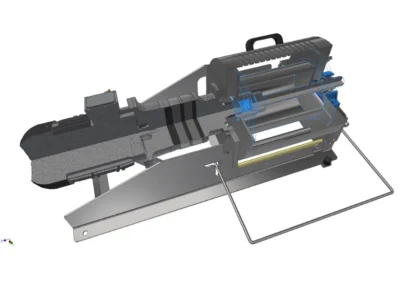

The project started with the production of a prototype based on the initial solution from the end customer. After evaluation and product maturation, an updated prototype was subsequently produced based on an all-electric solution. In addition to simplifying the control part, everything from usability, design, ease of manufacturing, ease of transportation/logistics and minimal service and maintenance were reviewed to collaboratively deliver the optimal product. A project where product development and the “Design for manufacturing” (DFM) discipline has been at the forefront!

After approval of the final solution, the winch unit is delivered as a CE-marked serial production. The game unit itself is used to pull planes into a hangar after landing.

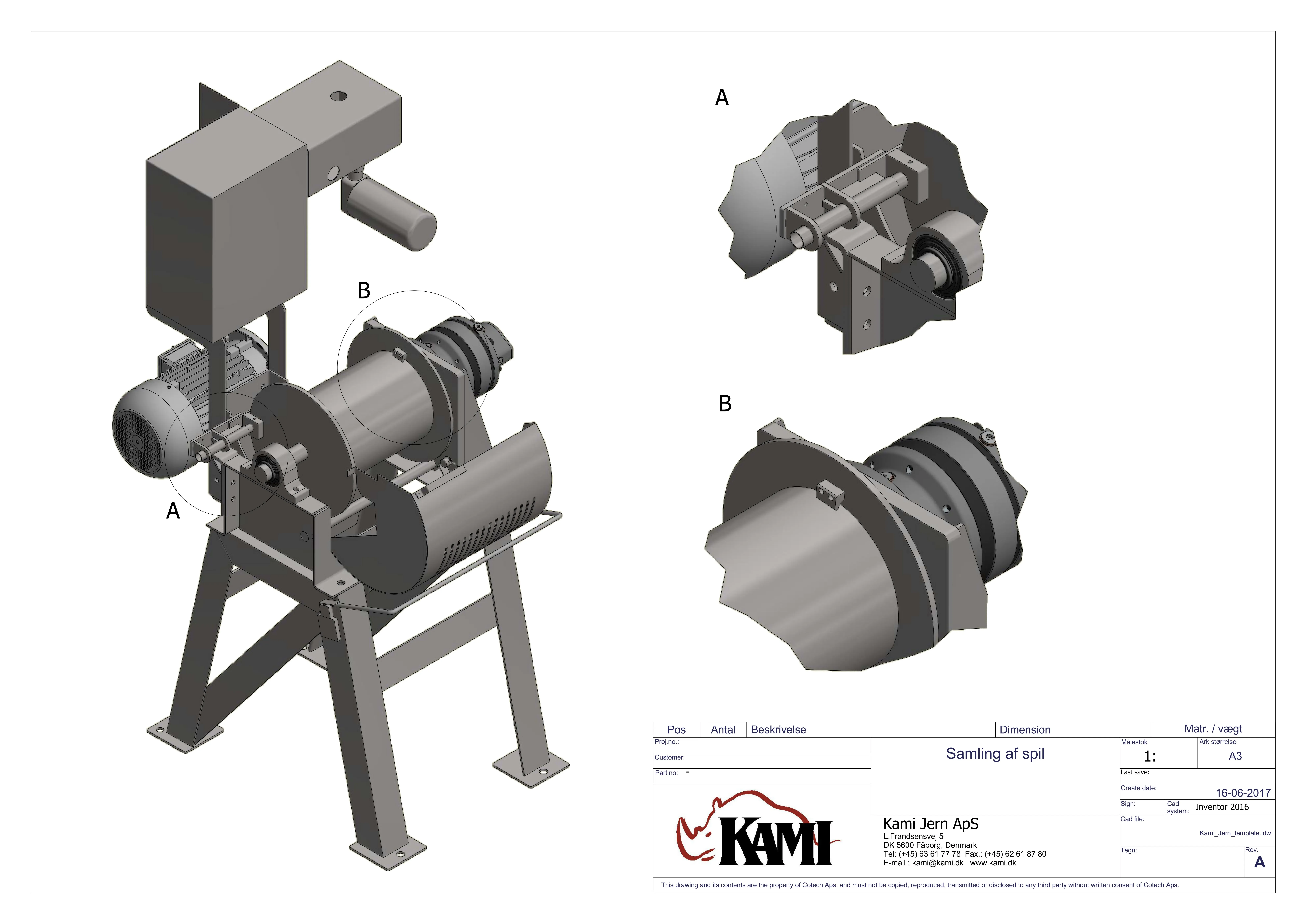

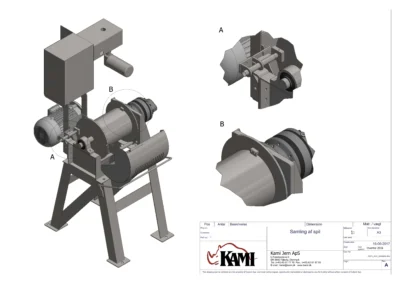

Construction

- KAMI’s engineering and production departments have jointly optimized the original requirement specification for the steel structure.

- Subsequently, the complete product including the steel delivery has undergone a Design for Manufacturing (DFM) process in collaboration with the control supplier to optimize the complete product.

- The focus has been on fast manufacturing and assembly, as well as simple testing and handling of the unit.

- Aspects such as ease of commissioning/operation and service are also discussed with the control supplier.

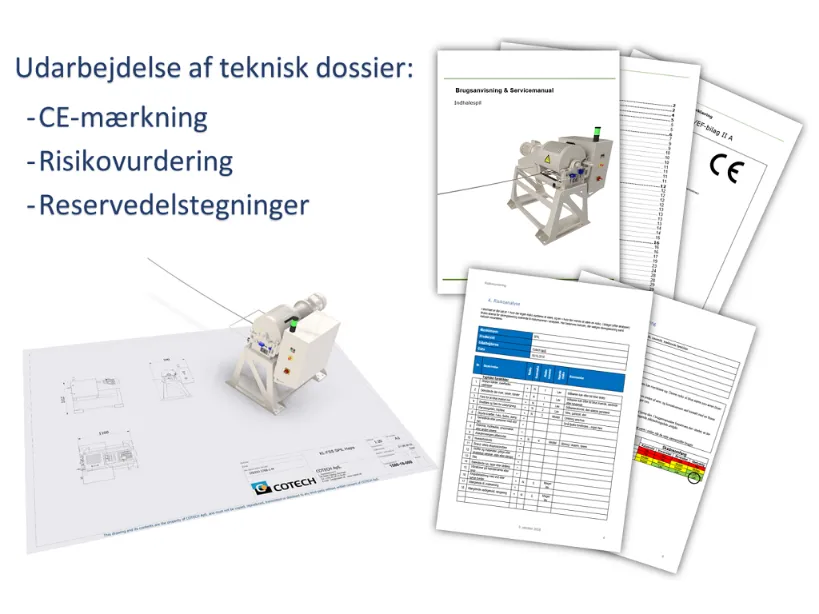

- After review, the mechanical construction of the winch unit is documented.

- A complete production basis has been prepared.

- Finally, all documentation regarding CE marking has been prepared.

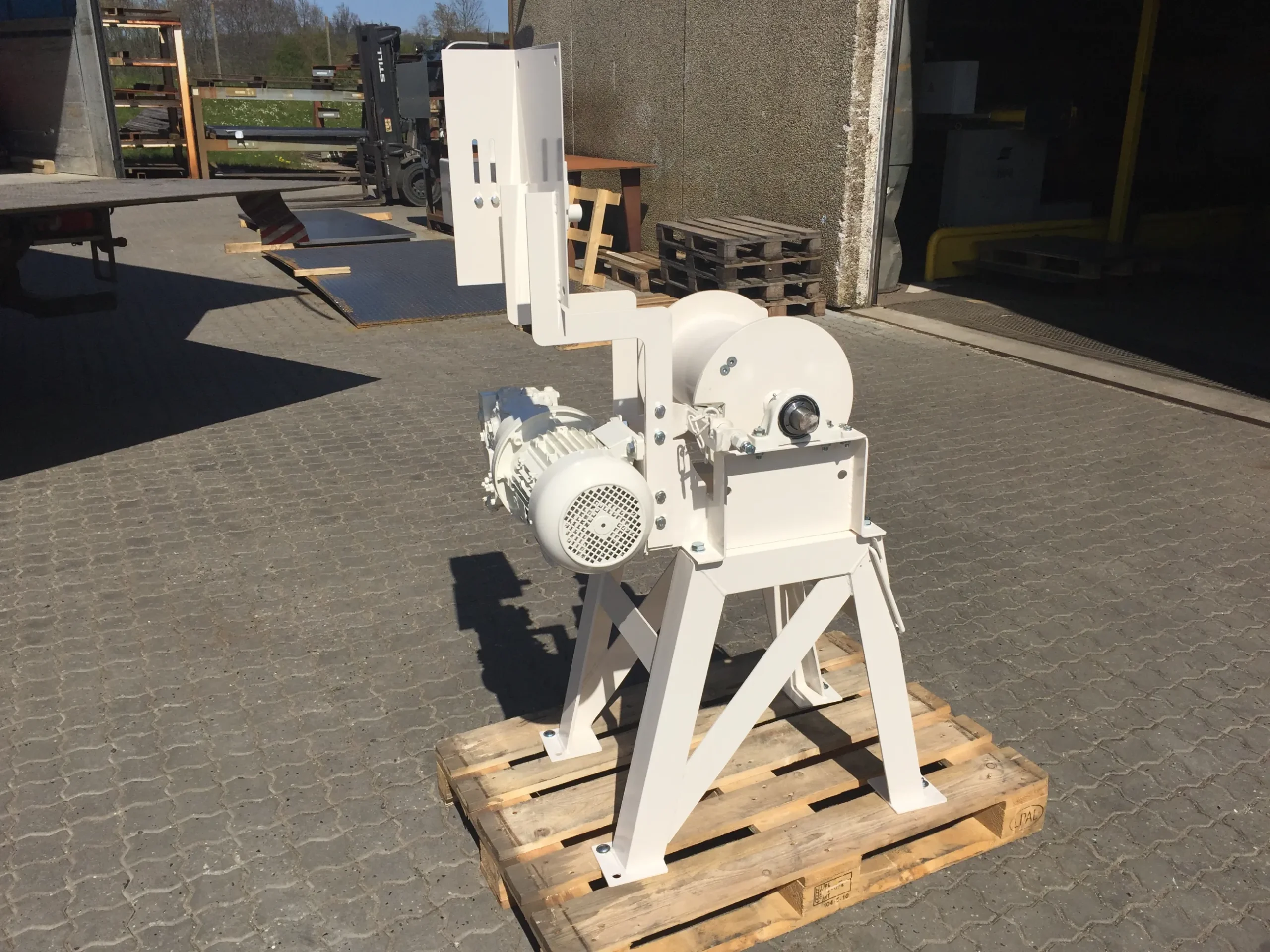

Production

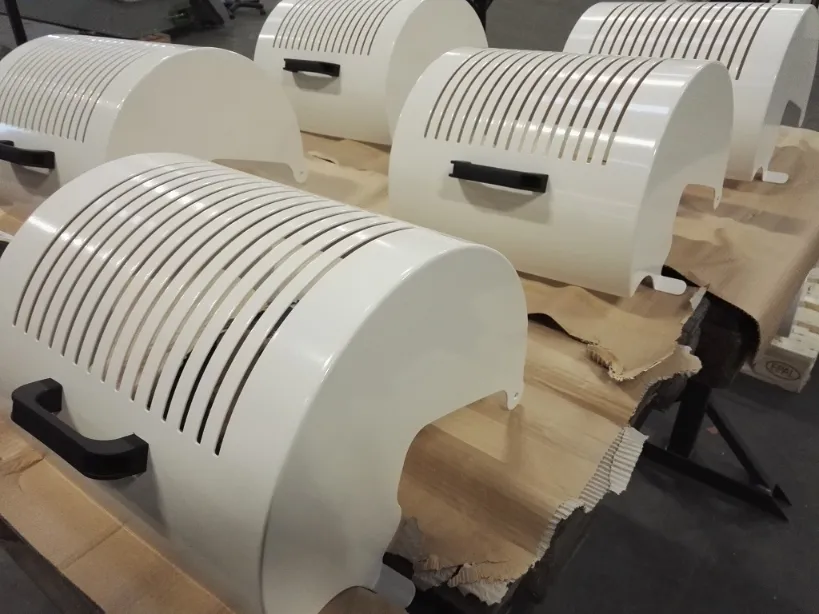

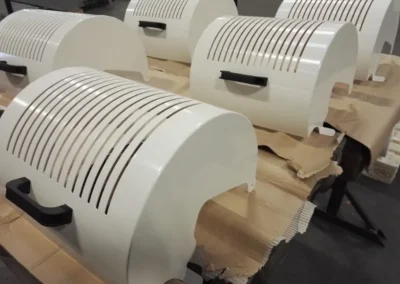

- KAMI’s black steel manufacturing section has produced gaming units.

- Processes include cutting, rolling, CNC machining, welding and assembly.

- Delivery and FAT testing of prototype

- Modifying and implementing fixes on prototype

- Subsequent delivery of series production.

Delivery

- The delivery is delivered to our customer and the end customer is located in Denmark.

- KAMI participated in the final testing of the original prototype in collaboration with relevant stakeholders and modified the mechanical part before starting the updated prototype.

- KAMI has delivered everything related to the mechanical part.

- We have prepared the production basis and produced the steel parts, carried out the assembly and handled CE marking.

We work within Industry, Offshore & Marine, and Structural Steel

We deliver everything from small welded structures to large structures!

We also deliver small CNC machined parts – and nothing is too small!

Engineering and project delivery

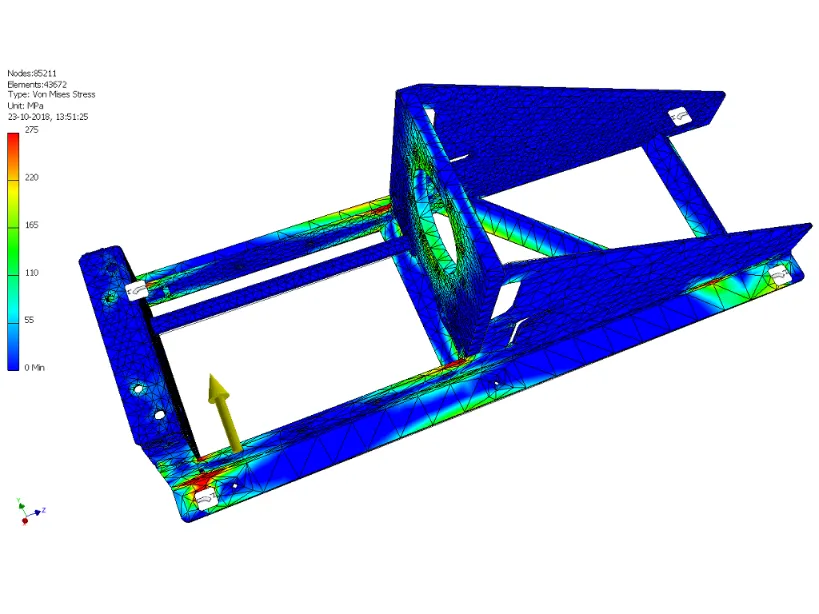

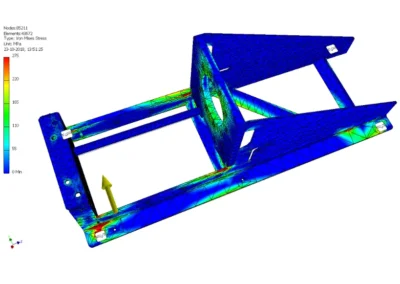

We offer design, FEM calculation and CE marking

Stainless steel and aluminum production

We offer sub-processes or complete designs

Production in mild steel and high-strength steel

We deliver everything in sheet metal, welding and machine work

Want to learn more about this project?

Feel free to contact us for more information!

We carry out many varied projects in stainless steel, aluminum as well as black and high-strength steel – for all kinds of industries. One of our strengths is that we can help you with technical sparring when you need a project done. The right design solutions and related production optimization are part of our everyday life. If you want more information about some of our project deliveries to industry, you can find more information here. In addition to industrial projects, KAMI also delivers projects for offshore & marine – more info about our deliveries to these segments can be found here.

In addition to project deliveries, KAMI delivers all kinds of different sub-processes to the metal industry. If you want to see and read more about the metalworking processes we offer, you can find information about them here. In addition to production, KAMI also offers separate engineering services, such as mechanical design, production documentation, FEM calculations and documentation, such as CE marking. If you want to know much more about the engineering services we offer, here’s an overview here.

Feel free to contact us – we’re ready to help you find the right solution!