Design via 3D scanning

Design via 3D scanning

If you need a 3D design based on a 3D laser scan, we can handle the task. We can also help you with the actual scanning if you want our help with that part of your job. With the help of a prior 3D scan before the construction process starts, we can ensure a project process where, for example, there are no surprises when the installation starts on-site.

We can design from 3D scans

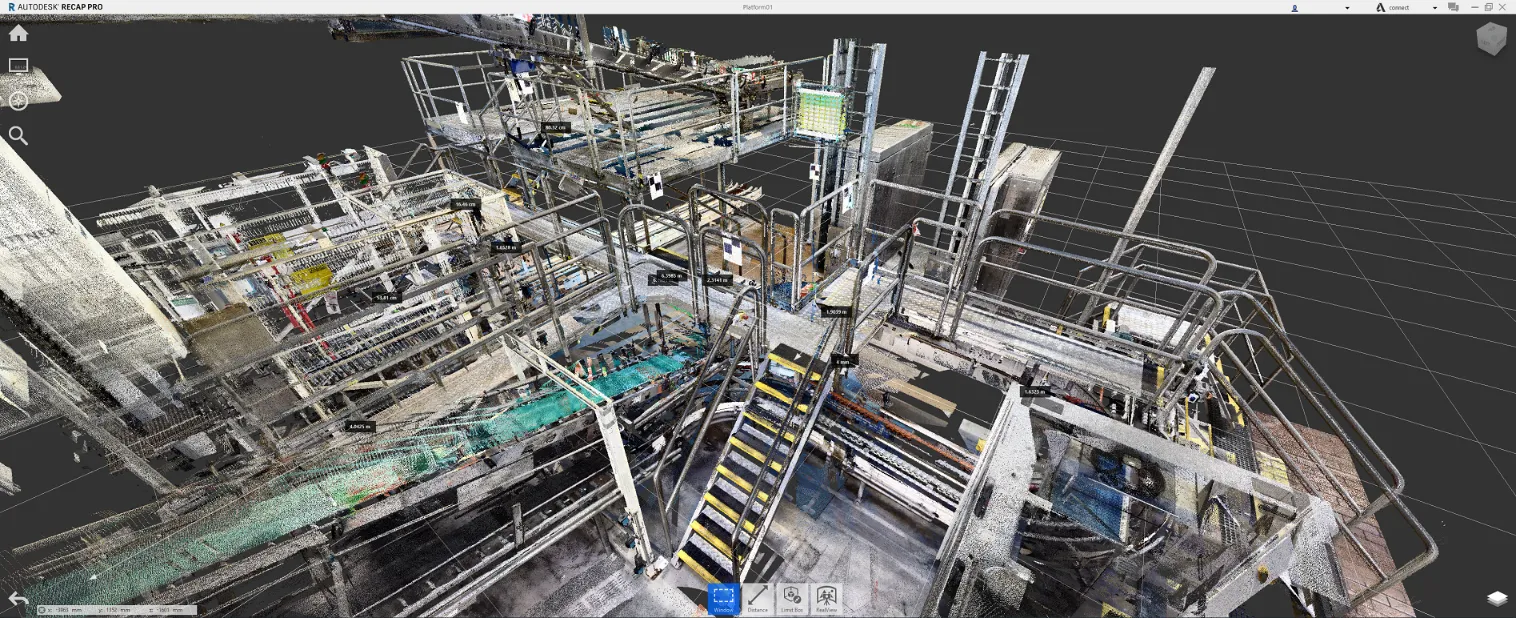

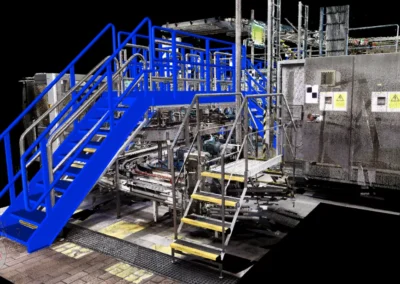

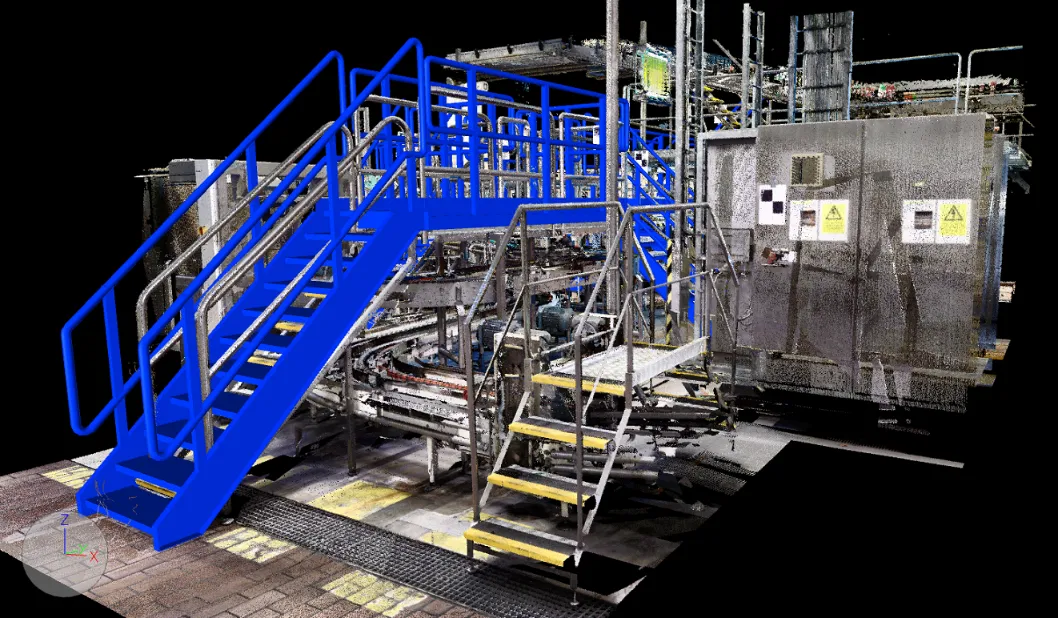

Using Autodesk ReCap and Autodesk Navisworks, our design team can access existing 3D scans and from these we can start the design process. If 3D scanning has not already been done, we can also take care of that part of the process. The advantage of working from a 3D scan is that you can ensure that the design fits in with the physical facilities at the location. Instead of a physical survey, a 3D laser scan can be performed to map all piping, access routes, conveyor belts, etc. With the help of a 3D scan, you can avoid missing important details in a factory layout or production line, for example.

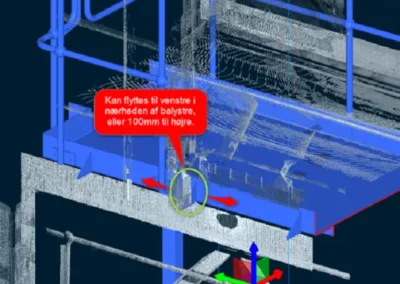

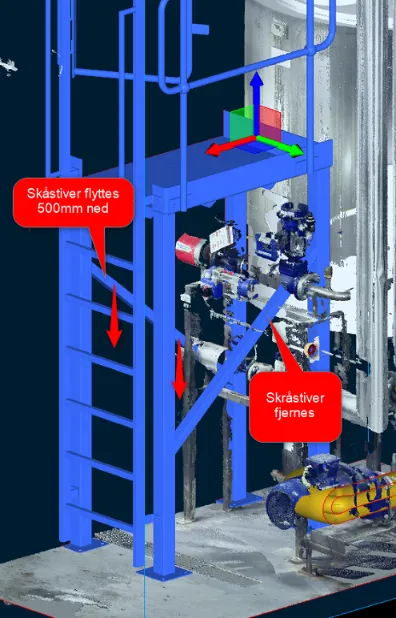

Potential clashes can be avoided early in the design process

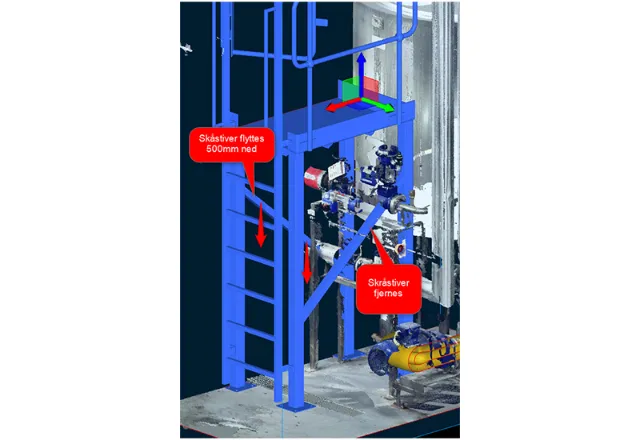

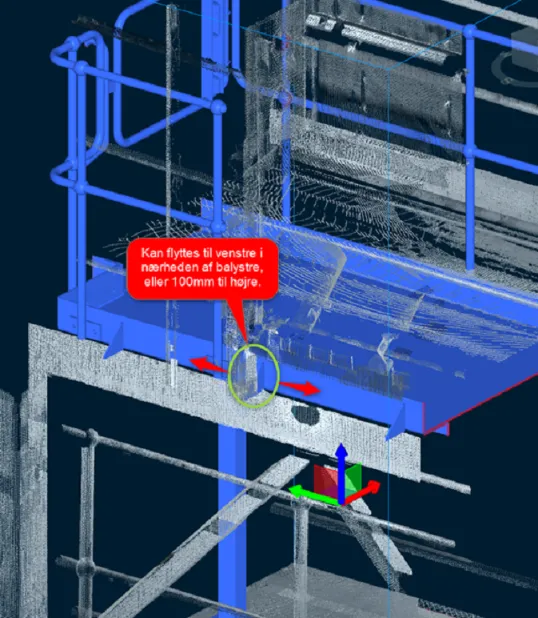

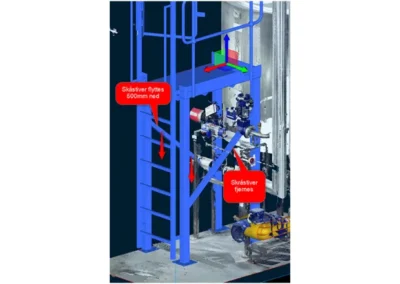

The combination of 3D scanning and subsequent construction ensures that the obvious – and not so obvious – clashes can be avoided and averted early in a project. Therefore, if you value the certainty of a smooth and fast project execution without setbacks, 3D scanning can be a good idea – our design department has extensive experience with the process.

Focus on high productivity, short lead times and a smooth project flow

Designing from 3D scans can significantly increase productivity and consequently reduce the lead time on a given project. In most cases, the need for additional surveying is not necessary and can often be eliminated altogether. In our software, we have the ability to insert constructions and 3D models directly into the 3D scanned point cloud, creating a very realistic image, giving you a strong visual insight into how a construction will look in reality. From this, you will be able to assess a design / layout in relation to the 3D scan. Based on this, a given design can be quickly and easily revised, and a product development process can also be reduced if interfaces are already known via a 3D scan.

We can help you with all tasks related to 3D scanning

If you have a 3D scan and a related task you would like to solve, such as incorporating a 3D model, or if you would like to have a 3D laser scan performed, please contact us. Below are some of the options we offer when it comes to 3D scanning:

- Measurement tasks in 3D with ReCap or Navisworks

- Preparation of all types of design tasks from 3D scans

- Testing for potential clashes and validating a 3D model

- Updating a 3D layout by inserting, for example, DWG files

- Produce high-quality images based on inserted 3D models in different locations in 3D scans

The possibilities in relation to 3D laser scanning and a derived construction process are many, and we would like to offer our knowledge so that you can use the technology for an optimal project process – please contact us for a chat about your specific task!

Contact us if you have an engineering task

KAMI’s design department provides many different engineering services! Among other things, we perform 3D design / mechanical designand we prepare production basis / working drawings, and can handle FEM calculations. In addition to design and calculations, we also offer various forms of documentation, including CE marking. If you wish, our construction department can offer you visualizations and preparation of piping diagrams (P&I diagrams). In addition to engineering, we can offer your steel production – contact us if you have an engineering task or if you want a quote for production – we are ready to serve you!

Contact us to find out what we can do for you

We also offer services like these

Visualization

P&I diagrams