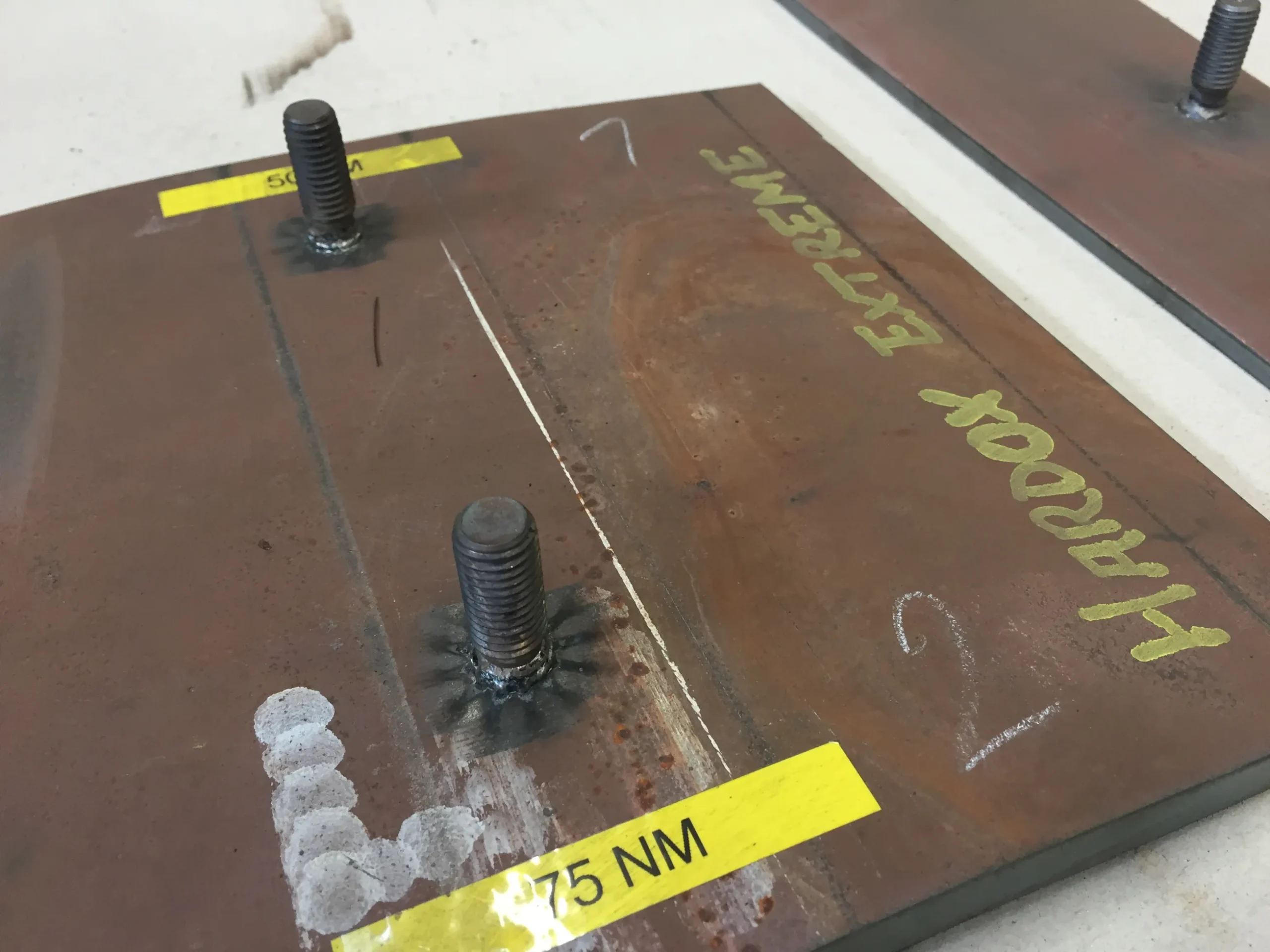

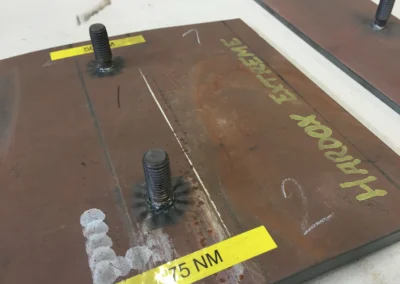

Bolt welding

Bolt welding in high-strength steel and other materials saves time

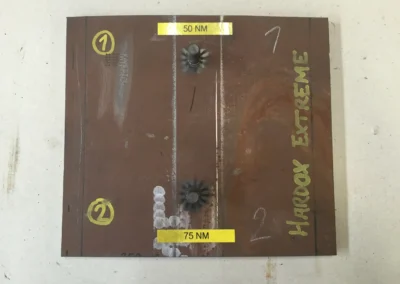

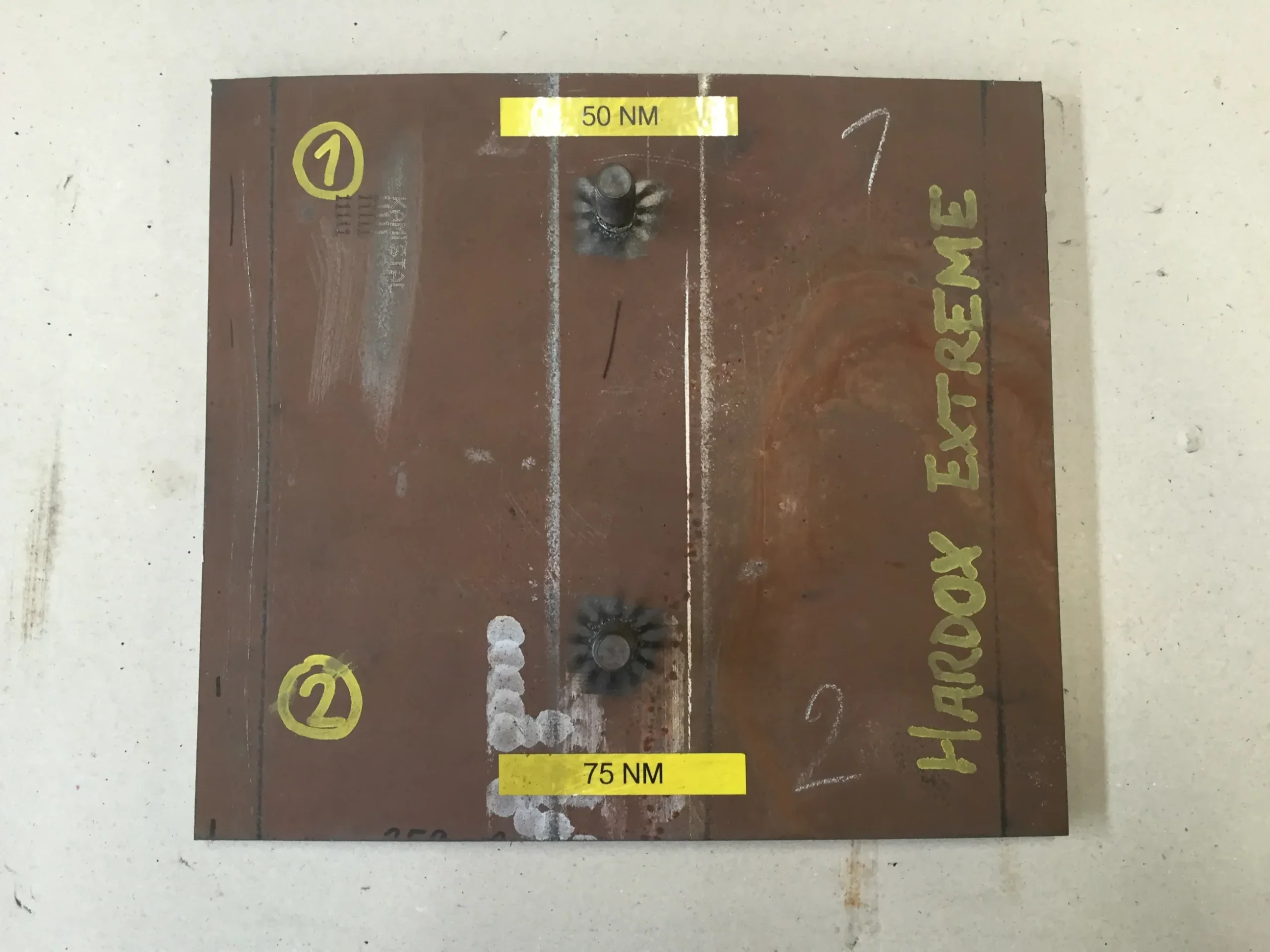

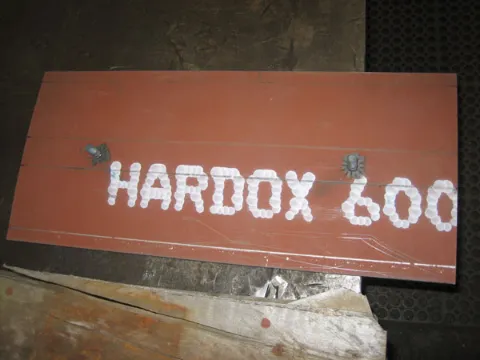

KAMI performs stud welding in a variety of materials, including high-strength steel.

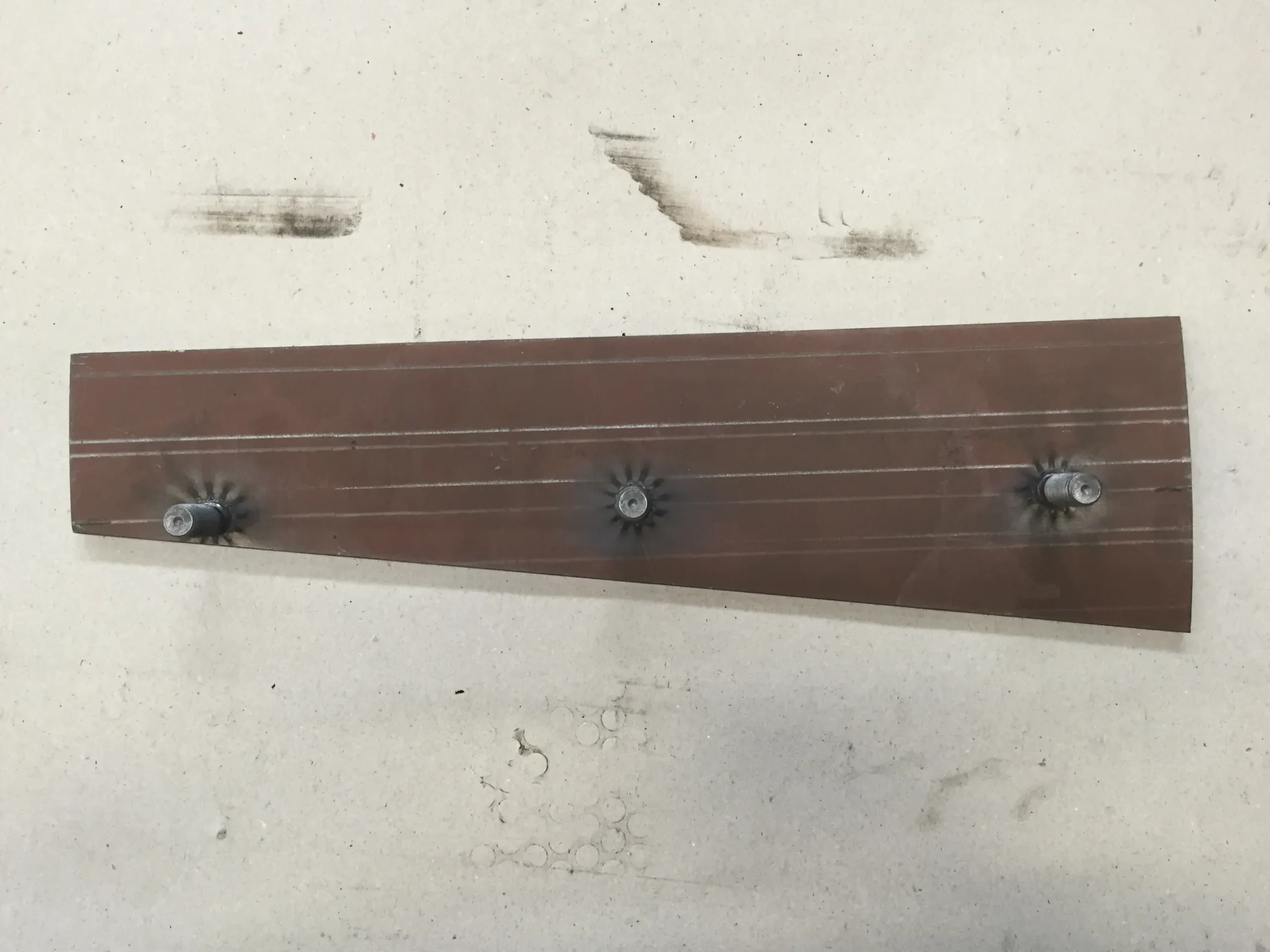

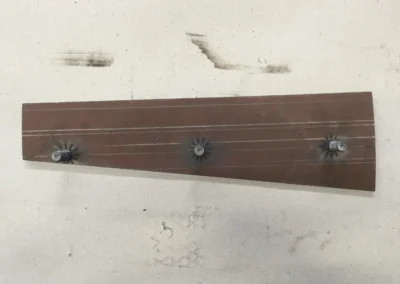

Stud welding is a process that is very time-saving and eliminates the need for any post-processing after the weld. At KAMI, we use the stud welding process to weld bolts on wear parts and more.

When we stud weld, the studs fit the hole pattern on the machine/construction. Without the need for subsequent grinding or straightening, the wear parts fit after stud welding without any adjustments.

Bolt welding comes with quality documentation

In addition to stud welding, we also perform tensile testing of the welds so that we can document that what we deliver complies with what is specified.

According to the specifications provided by you – or what we specify in collaboration – we create the test procedure, which our employees then follow based on instructions/directions.

This way, we ensure that the quality we have agreed upon is maintained at all times!

Quality assurance is part of everyday life at KAMI!

Our quality quality management system is certified according to DS/EN ISO 9001:2015 standard, and we always want to live up to what we agree with you! Delivery time, price and quality must always meet your expectations – we want to be your preferred supplier of bolt welding and other services.

Contact us to learn more about the possibilities with stud welding

Contact us and let us help you clarify your bolt welding options.

Read more about our different types of welding: Aluminum welding, stainless steel welding, high-strength steel, black steel welding, robotic welding and much more.

KAMI – we help with advice and guidance when you need stud welding

Contact us to find out what we can do for you

We also offer services like these

TIG welding

Welding in black steel