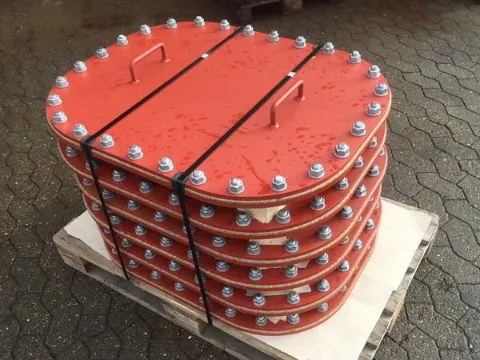

Ship hatches and covers

KAMI manufactures customized ship hatches

KAMI manufactures custom solutions and ship hatches and covers can be made in black steel, stainless steel or aluminum. Quality is ensured through our DS/EN ISO 9001:2015 quality management system, and in addition to our ISO certification, we are certified to perform welding according to EN ISO 3834-2.

All hatches and covers can be supplied with insulation and gaskets – so they are tailored to your sealing needs, such as weatherproof and spill-proof.

Fast delivery time – and we can create a production basis

If delivery time is critical and the solution needs to be custom-made, KAMI can handle the engineering part for you via our in-house engineering department – and then we can manufacture the right solution! If you have the drawings, we can of course also manufacture according to your specific production documentation.

We control quality and can secure approval via the classification society

Depending on the requirements of the products, KAMI’s certifications enable us to meet the requirements of classification societies such as DNV GL or Lloyd’s. We are used to working according to classification society guidelines, both in terms of design and manufacturing. KAMI employs its own engineers – so we can also help with the documentation part. We can handle both the design part and subsequent manufacturing. We can also take care of all contact with 3rd parties.

KAMI has its own cutting facilities and thus offers in-house traceability. Welding is ensured by our own welding coordinator, and we can weld according to WPS / WPQR and prepare Welders Log.

NDT and 3rd party inspection can be coordinated to offer a complete solution.

We ensure surface treatment in the desired specification

Surface treatment is done according to DS/EN ISO12944-C5M, as well as MOTS and Norsok standards, or galvanized, and all can be delivered with measurement report / FROSIO reports if desired.

In addition to supplying ship hatches and covers to Danish shipyards and shipping companies, KAMI has supplied many other different solutions to the offshore and marine industry that have been surface treated to the desired specification.

Contact us to learn more about delivery of ship hatches and covers

If you are interested in hearing about the possibilities for delivery of ship hatches and covers, please contact KAMI.

We work within Industry, Offshore & Marine, and Structural Steel

We deliver everything from small welded structures to large structures!

We also deliver small CNC machined parts – and nothing is too small!

Engineering and project delivery

We offer design, FEM calculation and CE marking

Stainless steel and aluminum production

We offer sub-processes or complete designs

Production in mild steel and high-strength steel

We deliver everything in sheet metal, welding and machine work

KAMI also provides projects, sub-processes and engineering

KAMI carries out many different projects in stainless steel and aluminum, as well as in black steel and high-strength steel. In addition to ship hatches and covers, as well as projects for the marine & offshore industry, KAMI also delivers projects for industry including the food industry. For more information on some of the projects we have delivered to industry, please see here. Examples of projects KAMI has delivered to the marine & offshore industry can be found here.

In addition to supplying ship hatches and covers as well as complete projects, we also supply a lot of sub-processes to the metal industry. For example, we offer cutting, bending/rolling, CNC machining and welding in mild steel and stainless steel. What we offer you can see here.

In addition to production processes, we also provide separate engineering, such as design work, FEM calculations and CE marking. You can read more about everything we offer in engineering here.

Feel free to contact us with your inquiry – we will do everything we can to help you further.