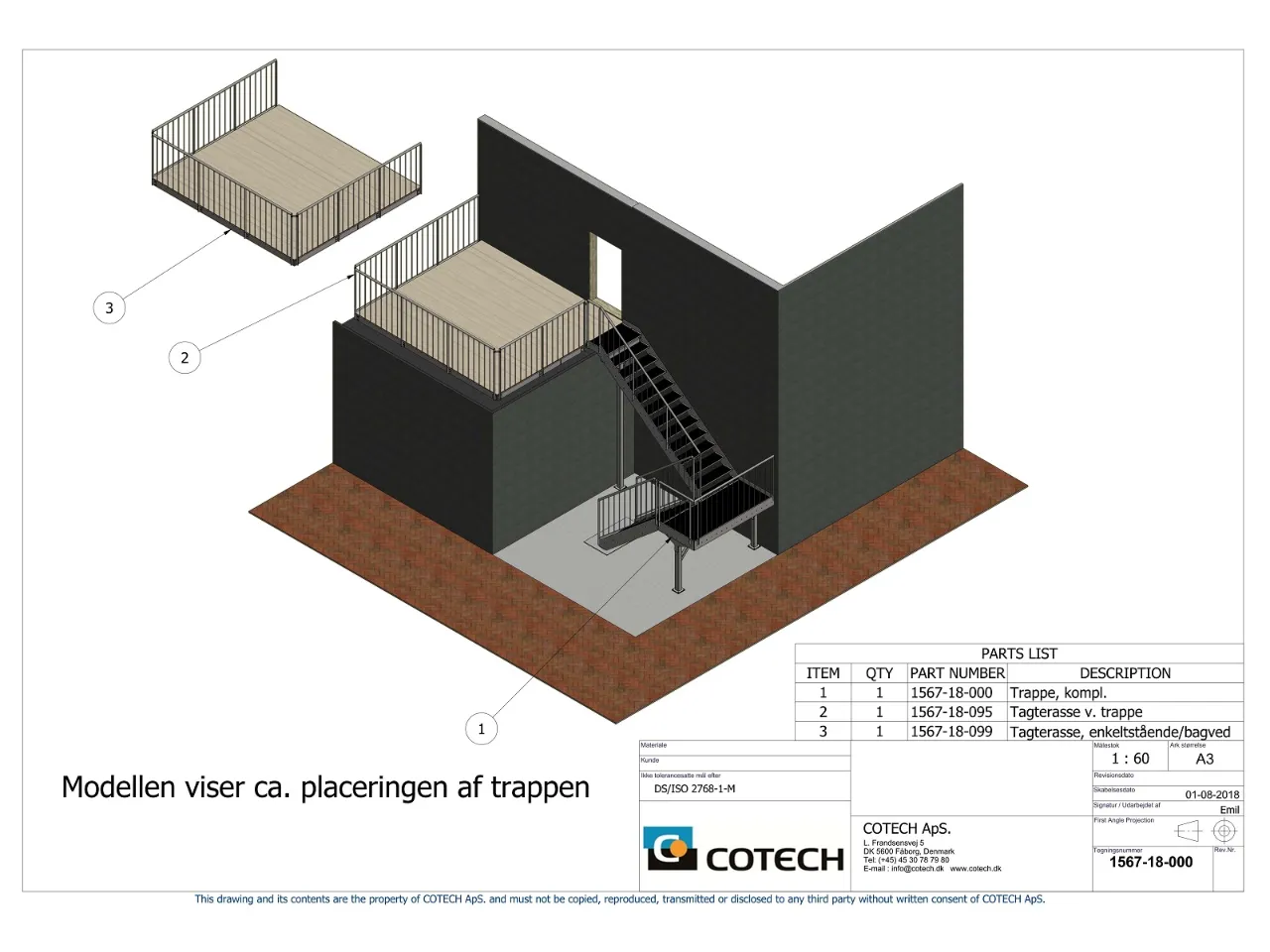

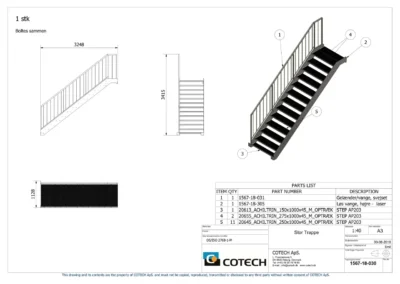

Staircase with roof terrace for construction

KAMI designed, manufactured, delivered and installed a staircase and terrace for an existing building

Our engineering and production departments worked together to deliver this complete steel solution – assembled at the customer’s site.

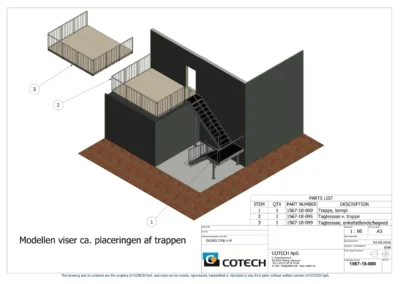

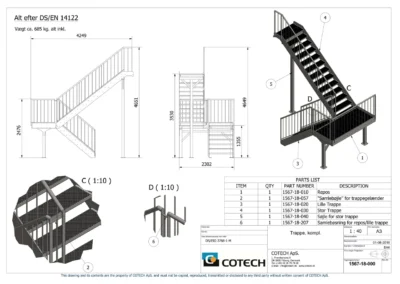

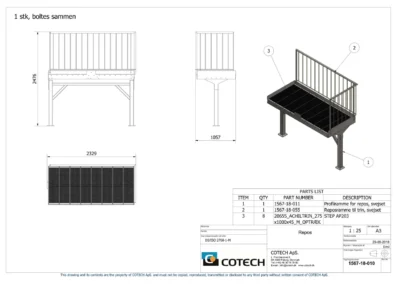

The request was for KAMI to design a staircase and railing that resembled the surrounding existing steel structures. After some design proposals, the final design was approved and calculations were performed. In addition to securing approval from the customer, we have taken care of the final measurement – based on the customer’s wishes for the placement of the staircase and terrace. Coordination/contact with relevant tradesmen is also handled by our engineering department. Optimization of the production basis after design determination was handled between our engineering and production departments, and finally, working drawings were created.

The staircase and railing to the terrace serves as a staircase to 2 apartments and is produced according to drawings. Finally, the steel contract is erected and installed at the customer’s site.

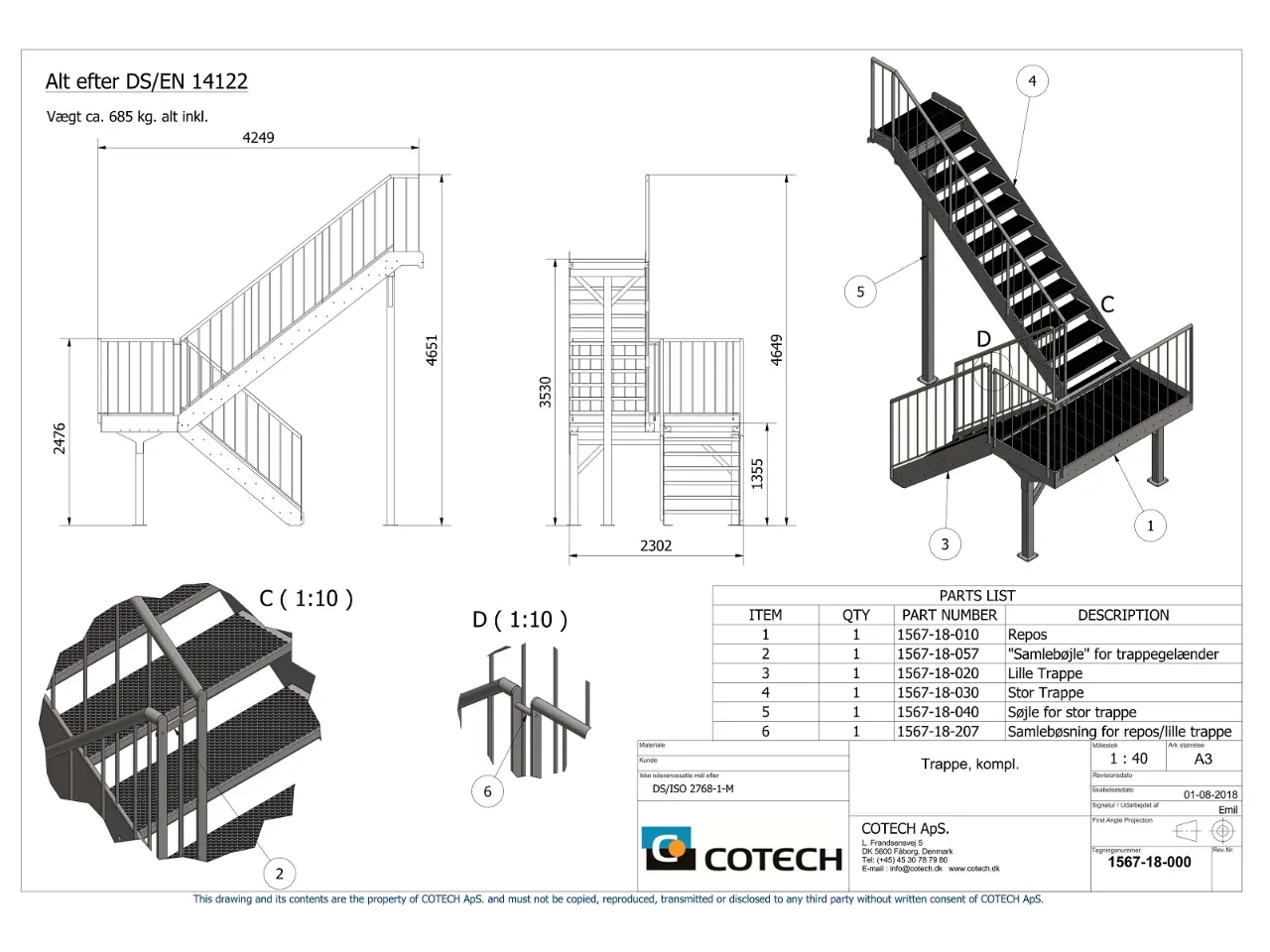

Construction

- KAMI’s engineering department has carried out initial measurements at the customer’s site.

- Designs are approved by the customer after preparation of relevant design briefs.

- The focus was on design/aesthetics and simplicity of manufacture – the design of the staircase and railing had to fit in with the existing environment.

- All coordination with the builders is done by KAMI’s engineering department – this has saved the customer unnecessary wasted time.

- The staircase and railing are designed so that the steel contract complies with the ISO 14122 standard.

- Calculations and final production basis / working drawings have been prepared.

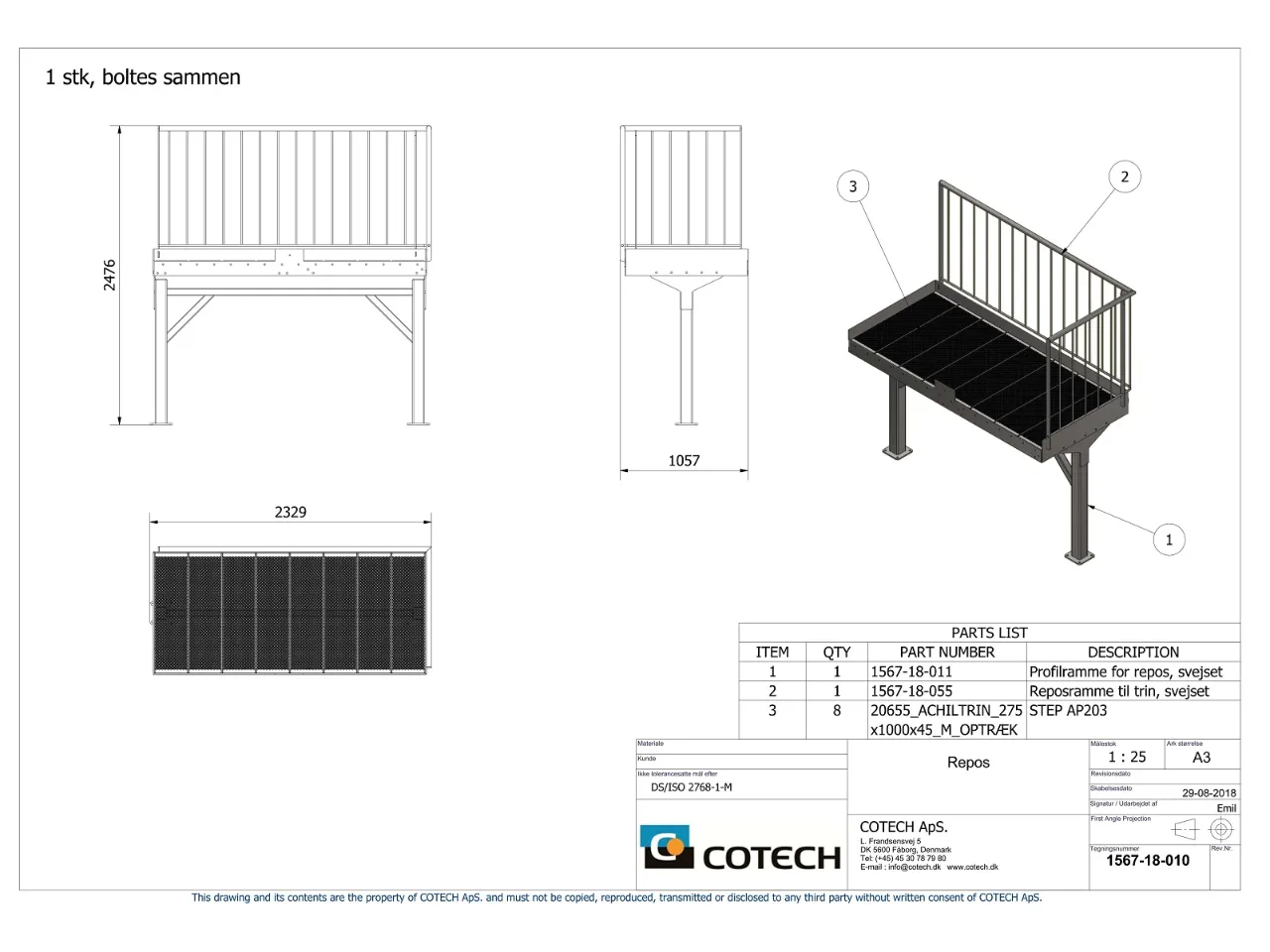

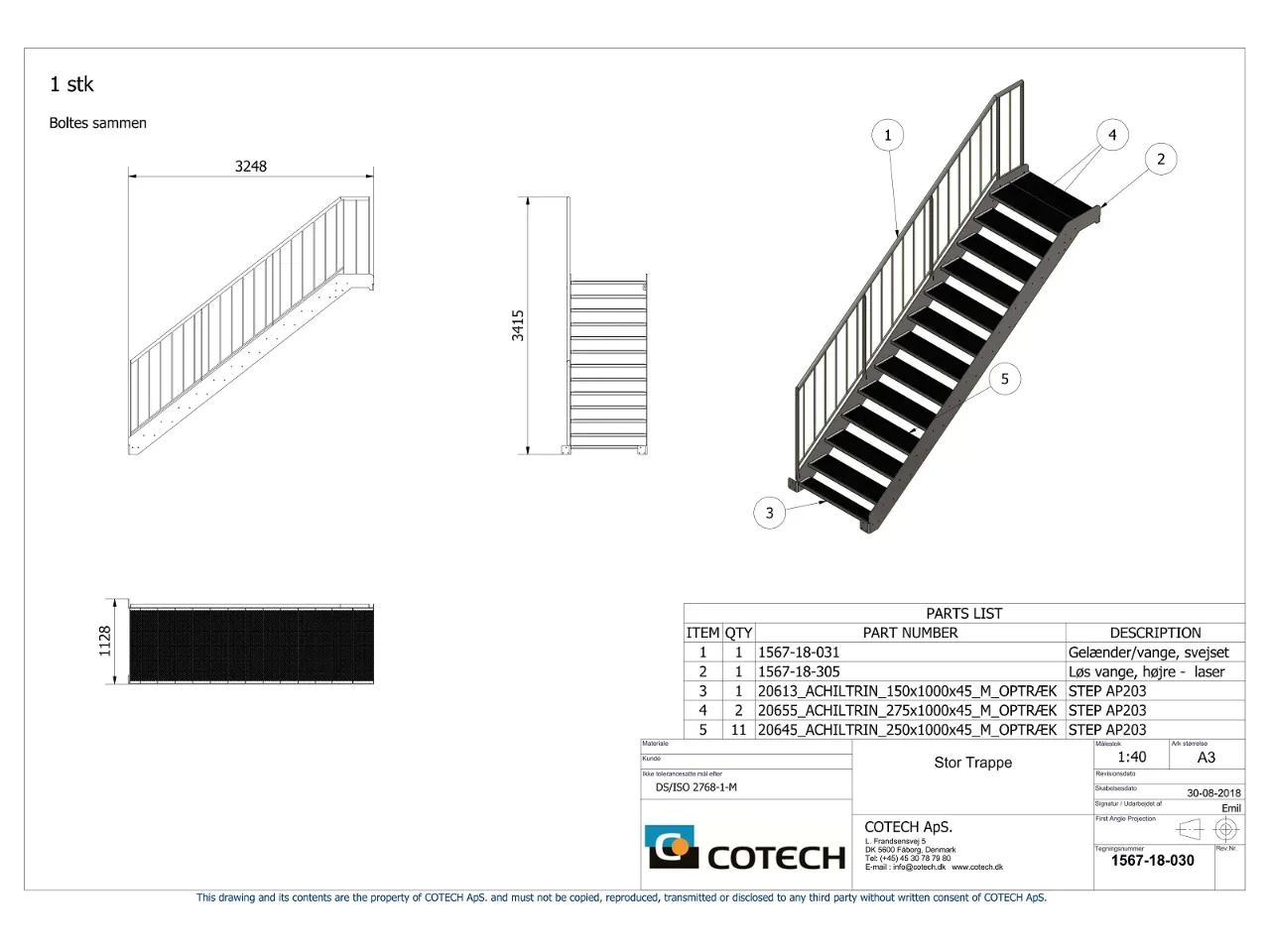

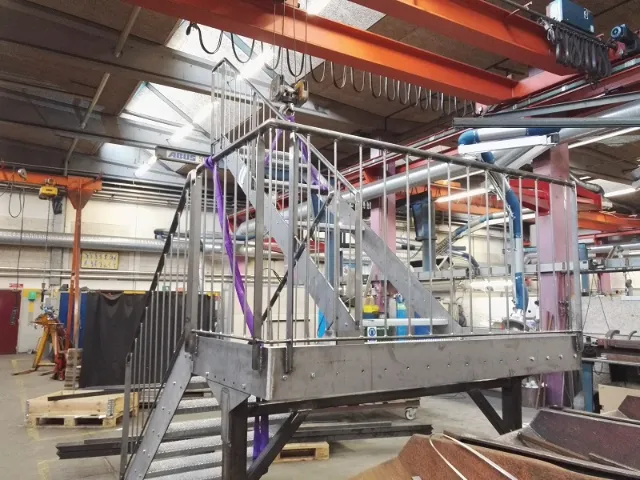

Production

- KAMI’s production has manufactured steel stairs and terrace railings in black steel.

- Inbound production processes have included cutting, bending and welding.

- The staircase and railing are powder-coated and the staircase is delivered with galvanized steps.

Delivery

- The staircase and veneer are installed at a customer’s site in Denmark.

We work within Industry, Offshore & Marine, and Structural Steel

We deliver everything from small welded structures to large structures!

We also deliver small CNC machined parts – and nothing is too small!

Engineering and project delivery

We offer design, FEM calculation and CE marking

Stainless steel and aluminum production

We offer sub-processes or complete designs

Production in mild steel and high-strength steel

We deliver everything in sheet metal, welding and machine work

Want to learn more about this project?

Please contact us for more information!

KAMI delivers a wide range of projects in stainless steel, aluminum, black steel and high-strength steel – for many different industries. We can help you with technical advice and clarification if you need to develop a project. KAMI is committed to being solution-oriented, and production optimization and cost out is a natural part of what we do!

For more information and to see more of our project deliveries to industry, you can find more info here. In addition to industrial projects, we also provide project deliveries to the offshore & marine segment – info on some of these projects can be found here.

In addition to projects, we supply many different sub-processes to the metal industry. Info on which metalworking processes we can offer can be found here. In addition to production, we can offer separate engineering services, for example mechanical design, production documentation / working drawings, FEM calculations and documentation – including CE marking. Which engineering services we can help you with can be found via the link here.

Remember, you are always welcome to contact us – we will help you deliver the best solution in terms of price, quality and fast delivery!