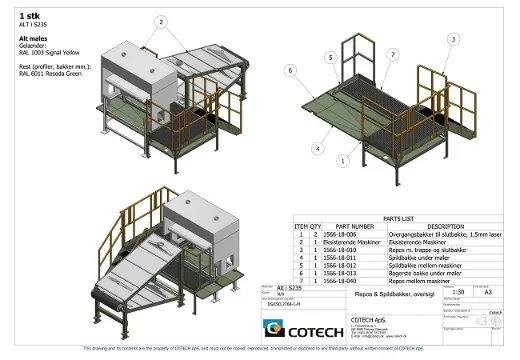

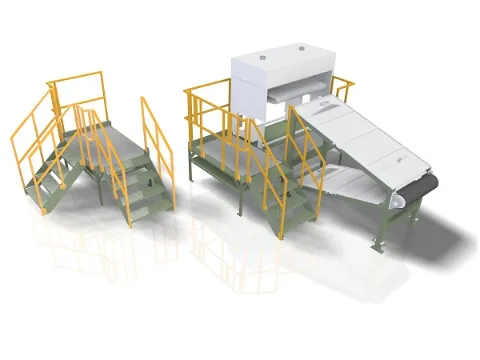

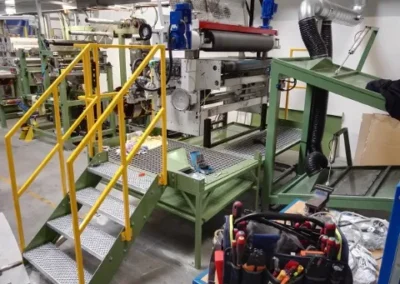

Repos and machine stand for painting line

KAMI has designed, manufactured and delivered a landing with guardrails according to the EN ISO 14122 standard

Working together, our engineering and production departments have delivered a finished solution, ready for installation at the customer’s site.

Due to time constraints, we were given the total delivery as we were able to minimize the lead time for the customer with a total solution. The customer provided a STEP 3D CAD file of the overall system, and after a measurement and clarification meeting with the customer, our engineering department prepared a proposal for a solution. After minor corrections, the solution was approved and based on the acceptance, the complete production basis was created.

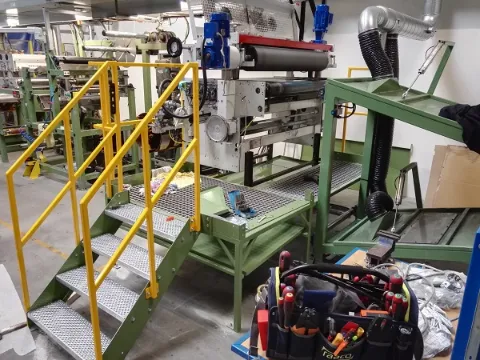

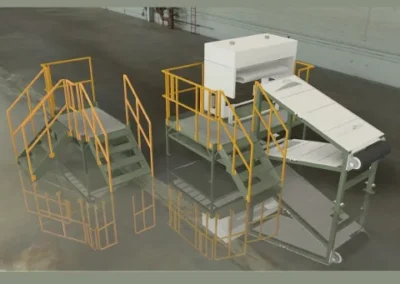

KAMI has designed the machine stand and rest for inspection/servicing on part of a production line. The finished solution includes a landing, machine rack and various spill trays for collection. The solution, where the guardrails are based on the EN 14122 standard, is implemented in a large painting line set up as part of the production in a factory.

Construction

- KAMI’s engineering and production departments have worked together to deliver the right solution with a focus on simple manufacturing and assembly.

- “Design thinking has been part of the solution – for example, the staircase can be mounted in multiple locations on the landing, giving operators freedom of choice in terms of access to the production line.

- Construction of repos according to EN ISO 14122

- Preparation of complete production documentation.

Production

- KAMI’s production has manufactured repos, guardrails, machine stands and spill trays in black steel.

- Processes to complete the project include cutting, bending, welding and test set-up.

- The solution is powder coated in 2 different RAL colors.

Delivery

- Repos with accessories have been delivered to a customer in Denmark.

- The delivery is delivered and installed on-site at the factory.

We work within Industry, Offshore & Marine, and Structural Steel

We deliver everything from small welded structures to large structures!

We also deliver small CNC machined parts – and nothing is too small!

Engineering and project delivery

We offer design, FEM calculation and CE marking

Stainless steel and aluminum production

We offer sub-processes or complete designs

Production in mild steel and high-strength steel

We deliver everything in sheet metal, welding and machine work

Want to learn more about this project?

Feel free to contact us for more information!

We carry out many varied projects in stainless steel, aluminum as well as black and high-strength steel – for all kinds of industries. One of our strengths is that we can help you with technical sparring when you need a project done. The right design solutions and related production optimization are part of our everyday life. If you want more information about some of our project deliveries to industry, you can find more information here. In addition to industrial projects, KAMI also delivers projects for offshore & marine – more info about our deliveries to these segments can be found here.

In addition to project deliveries, KAMI delivers all kinds of different sub-processes to the metal industry. If you want to see and read more about the metalworking processes we offer, you can find information about them here. In addition to production, KAMI also offers separate engineering services, such as mechanical design, production documentation, FEM calculations and documentation, such as CE marking. If you want to know much more about the engineering services we offer, here’s an overview here.

Feel free to contact us – we’re ready to help you find the right solution!